Model : CASS-1000H

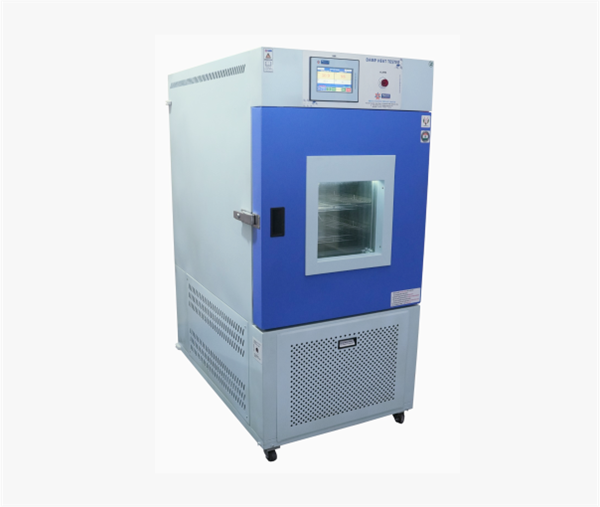

A Salt Spray Chamber, also known as a Cass Cum Salt Spray Chamber, is an advanced corrosion testing instrument designed to assess the performance and durability of surface coatings, metallic materials, and component finishes under accelerated corrosive conditions. This chamber replicates a highly saline, fog-like environment similar to what materials experience in coastal or industrial atmospheres.

A Salt Spray Chamber, also known as a Cass Cum Salt Spray Chamber, is a precision-engineered corrosion testing equipment designed to evaluate the resistance of coatings, paints, and surface treatments against a saline or corrosive environment. This testing method, commonly known as Salt Spray Test (SST) or Salt Fog Test, helps determine how long a material or coating can withstand harsh environmental conditions before showing signs of rust or corrosion.

The Cass Cum Salt Spray Chamber is an advanced version of the traditional salt spray tester, following ASTM B117, ISO 9227, and JIS standards. It’s widely used in industries like automotive, aerospace, electronics, and metal finishing to ensure high-quality and durable surface protection.

The Cass Cum Salt Spray Chamber operates by atomizing a saltwater solution (typically 5% NaCl) through a fine mist nozzle inside a controlled testing chamber. Test samples are placed inside the chamber at a specific angle, allowing the mist to uniformly settle on their surfaces.

The chamber maintains controlled temperature, humidity, and spray conditions, simulating long-term exposure to corrosive marine or industrial atmospheres within a short period. The CASS (Copper Accelerated Acetic Acid Salt Spray) variant adds copper chloride and acetic acid to the saline solution, intensifying the corrosive effect for faster and more aggressive testing — ideal for evaluating decorative coatings such as nickel-chrome plating.

By observing changes like rust formation, blistering, or coating breakdown, engineers can accurately assess a material’s corrosion resistance and quality performance.

The Cass Cum Salt Spray Chamber is an essential tool for industries where corrosion resistance is critical. Common applications include:

Presto Instruments is a leading manufacturer and supplier of Cass Cum Salt Spray Chamber in UAE. For the best price, contact us for a quote or call now!

The chamber generates a fine mist of saltwater mixed with acetic acid and copper chloride, which continuously settles on the sample surfaces. By maintaining a constant temperature and humidity, the chamber accelerates corrosion. Test results are then analyzed for rusting, pitting, or coating degradation to measure durability.

A Cass Cum Salt Spray Chamber is a corrosion testing machine that simulates a salty, humid environment to evaluate the corrosion resistance of metals, coatings, and surface finishes. It uses a copper-accelerated acetic acid salt spray (CASS) solution for faster and more aggressive testing compared to standard salt spray tests.

This chamber is suitable for a wide range of materials and coatings, including:

The chamber is designed according to major international standards, including:

These ensure reliable and globally accepted test results.

It’s widely used in:

The Bench UV Light Accelerated Weathering Tester is a compact and efficient laboratory device designed to simulate long-term outdoor exposure in a controlled environment. Using high-intensity UV light, temperature control, and optional moisture cycles, it quickly reveals how materials will fade, crack, or degrade over time.

Read More

The UAE's high-temperature conditions create a significant challenge for industries that are quality-sensitive. Material degradation, reduced product durability, and disruption in critical testing are feared due to temperature and humidity level changes. This would mean giving mediocre products that do not meet international standards one can only imagine the level of dissatisfaction from customers and revenue loss.

Read More

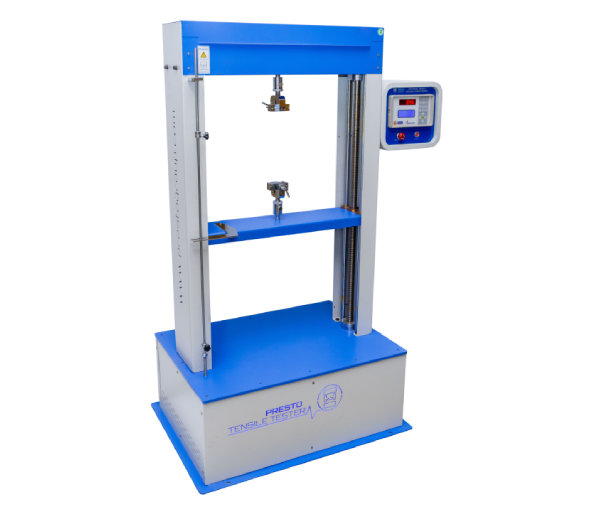

Presto's newly launched Zeus Ultimo 3.0 tensile testing machine is a top-quality lab instrument designed to assess the tensile properties of materials. This machine enables manufacturers to test the breaking, tensile, and compression strength of various materials, components, and finished products. It complies with numerous test standards,

Read More

The Hot Air Oven is a specialized testing chamber designed to detect changes in the physical properties of materials and determine their operational lifespan under elevated temperatures.

Read More

The Hot Air Oven – Touch Screen is a modern and reliable testing machine used to check how materials react to different temperatures. It comes with a full touch screen control system, a three-color tower alarm, and advanced safety features. Made with strong stainless steel and mild steel, it ensures long life and low maintenance. The oven provides even heating and stable temperature for accurate testing, making it ideal for rubber, plastic, and other material industries.

Read More

Presto introduces the cutting-edge Hot Air Oven Prima Series, a top-of-the-line testing equipment engineered to detect changes in the physical properties of materials and determine their operational lifespan under elevated temperatures.

Read More

The Presto Cyclic Test Chamber - CYKO is a high-precision environmental testing solution designed to simulate fluctuating temperature and humidity conditions. Ideal for assessing product durability, reliability, and lifespan, CYKO helps manufacturers and researchers identify potential weaknesses before products reach the market.

Read More

The Cass Cum Salt Spray Chamber (250 Litres) – Touch Screen is a high-performance corrosion testing machine designed to evaluate the durability of coatings, metals, and surface finishes under accelerated salt spray and CASS conditions. Equipped with an advanced touch-screen controller, it offers precise temperature, humidity, and spray cycle management for accurate and repeatable results.

Read More

To safeguard against corrosion in materials like metals and plated components, conducting a salt spray test is essential. This test evaluates the corrosion resistance of coatings and materials commonly used in products such as fasteners.

Read More

The Salt Spray Chamber, crafted in accordance with ASTM B117 and JIS 2371 standards, is essential for conducting the Neutral Salt Spray Test (NSS test) on metal surface coatings. It serves to evaluate the coating's resistance to corrosive environments by subjecting specimens to an accelerated salt-laden atmosphere.

Read More

An Impact Resistance Tester for Paint: Direct is a precision testing instrument used to evaluate how well a paint or coating can withstand sudden mechanical shock. Coatings in real-world environments often face accidental knocks, dents, and abrasion, and this tester simulates those conditions through a controlled vertical impact.

Read More

The Water Watch Digital is a stylish and durable smartwatch designed for active lifestyles. With advanced fitness tracking, heart rate monitoring, waterproof design, and smart notifications, it keeps you connected and healthy—whether at the gym, outdoors, or in water sports.

Read More

Edge Crush Prima is a premium corrugated packaging grade designed for superior edge strength and dependable load support. Engineered with high-density fibers and advanced construction, it ensures cartons stay firm, stable, and crush-resistant during stacking and transport.

Read More

The PTH Environment Programmable Temperature & Humidity Chamber provides controlled environmental testing with high accuracy and reliability. Perfect for R&D, electronics, automotive, pharmaceutical, and aerospace applications, it helps simulate real-world temperature and humidity conditions to identify product weaknesses and ensure superior quality.

Read More

The Benchtop Spectrophotometer is a high-accuracy color and light measurement instrument designed for laboratory and industrial quality control. It provides precise spectral data, reliable color matching, and excellent repeatability across a wide range of materials.

Read More

Introducing the TP800 Portable Spectrophotometer, a patented testing machine meticulously designed and manufactured by Testronix. This innovative testing instrument stands out for its exceptional performance stability, precise measurement capabilities, and a range of powerful functions that set the industry standard.

Read More

A color spectrophotometer is a specialized instrument crafted for precise analysis of physical samples through comprehensive spectrum color measurement. Distinguished by their ability to offer multiple illuminant/observer combinations and operate in various geometric arrangements, color spectrophotometers offer unparalleled flexibility and versatility compared to colorimeters.

Read More

A Haze Meter is a precision instrument used to measure the haze and total light transmittance of transparent materials. It helps manufacturers evaluate product clarity, detect defects, and ensure compliance with global quality standards. Ideal for plastics, glass, films, coatings, and optical components, it delivers fast, accurate, and repeatable results for reliable quality control.

Read More

The Damp Heat Test Chamber for Solar PV Modules is an advanced testing device that tests the performance and longevity of solar panels at high temperatures and relative humidities. This versatile piece of equipment is well suited for research and development (R&D), quality control, and development of certification for manufacturers of Solar PV Modules to produce solar PV Modules that will be of high quality, reliable and long-lasting results for end-user consumption.

Read More

Introducing the Presto Scratch Hardness Motorized Tester, a premier apparatus tailored for conducting scratch resistance tests under specified loads.

Read More

The Humidity Chamber - Touch Screen with Data Logger is designed to assess changes in the physical properties of materials under severe environmental conditions, such as varying humidity levels.

Read More

At Presto, we take pride in being Global manufacturers of Laboratory Testing Instruments for different industries.