Model : PPPD-0116 (DRO)

The profile projector is an optical device that enlarges and displays the shadow of a workpiece on a screen so it can be measured and inspected without touching the workpiece. It is sometimes referred to as an optical comparator or shadowgraph. Profile projectors are commonly used in quality control situations to precisely confirm the dimensions, angles, and surface characteristics of small or complex geometry parts by comparing the enlarged shadow to specifications.

A profile projector is a highly accurate optical measuring device that inspects the dimensions and shapes of small mechanical parts by projecting an enlarged silhouette of the part onto a screen, where you can compare it against standard charts or other methods for accurate measurement and comparison. The basic principle of operation is optical magnification or enlargement. The light passes through the part and forms an enlarged shadow on the screen for precise measurement and analysis.

A profile projector operates by projecting light onto a part to create an enlarged shadow, or silhouette, of that part. The enlarged image is then projected through lenses and mirrors to a screen. An operator then reviews the projected profile in comparison to grids or overlays for assessing the dimensions, angles, and shapes with exceptional accuracy and precision.

Here are the advantages of the profile projector explained in detail:

High Measurement Accuracy

A profile projector offers great accuracy by magnifying the shape of the part, allowing operators to notice even tiny differences in size. The optical system reduces human error and ensures consistent inspection. The accuracy it offers makes it suitable for quality control in industries where certain tolerances and tight specifications are critical to the proper performance of the product.

Non-Contact Inspection

Since the profile projector relies on light to capture the image of the component, it is able to determine without touching the sample. This leaves the materials free from deformation or damage. It is valuable for inspecting soft, small, or flexible parts that are unable to withstand the force of contact-based instruments, thus providing consistent and repeatable results during the inspection.

Easy Comparison With Standards

Grids, patterns, or overlays on the projection screen make it easy to compare the outline of the part against standard profiles or templates. This visual comparison makes it easy to spot defects or differences. The operator can easily check the dimensions, shapes, and angles of the components, which reduces inspection time and improves productivity in a manufacturing environment.

Suitable for Complex Geometries

Profile projectors can inspect complicated shapes, curves, threads, and non-standard profiles that conventional measuring devices have difficulty measuring. The enlarged silhouette makes it simple to inspect these challenging dimensions with ease. The ability to inspect such a wide range of components makes a projector ideal for industries such as automotive, electronics, and precision engineering, where parts often include complicated geometrical features.

Here are the major applications of the profile projector explained in detail:

Automotive Industry

Profile projectors are routinely used to verify engine parts, gears, shafts, and precisely machined parts. They are utilized to examine dimensions, angles, and thread profiles to make sure each part meets safety and performance specifications. Accuracy for quality assurance in mass production is paramount to reducing mechanical failures.

Electronics and PCB Manufacturing

In electronics, profile projectors can also be used to verify and measure smaller electronic parts, such as connectors, pins, microparts, and the edges of the PCB. This non-contact measuring method of checking very delicate parts prevents any damage during the inspection process. The magnified shadow of the electronic part being checked makes it easy to identify any dimensional discrepancies, which results in enhancing the quality of each assembly and the electronic parts being made for smaller electronic devices.

Medical Device Manufacturing

Medical devices such as surgical instruments, implants, syringes, and micro-mechanical parts have very strict dimensional tolerances and must be precise in every dimension and angle. Profile projectors allow parts to be inspected after they have been assembled and handled without any risk of touching them, losing their sterility, or having their structural integrity compromised.

Tool and Die Industry

Profile projectors are crucial when checking cutting tools and dies, punches, and molds. They can verify edge profiles, angles, radii, and the level of wear on cutting tools. Using a profile projector helps verify that the tools are creating parts that meet consistent and acceptable geometry. The frequency of checking cutting tools is crucial to maintain the length of their life and the manufactured dimensional properties, ensuring a high level of precision across a variety of machining methods.

Choosing Presto Instruments means investing in reliability, precision, and long-term performance. As a trusted profile projector manufacturer, Presto delivers robust optical systems, accurate measurement results, and user-friendly operation. They engineer their equipment to ensure consistent quality control, providing strong technical support, durable construction, and industry-proven performance for a variety of inspection applications.

Presto Instruments is a leading manufacturer and supplier of Profile Projector in South Africa. For the best price, contact us for a quote or call now!

Standard Magnification: 10X

Projector Screen Diameter: 300 mm

Field of View: 30 mm

X-Y Travel Range (with Gauge Blocks): 50 × 50 mm

Effective Table Dimensions: 275 × 180 mm

Measuring Unit: Built-in linear scales

Least Count / Resolution: 0.001 mm

Rotary Measuring Stage: Yes; Stage Glass Diameter: 70 mm

Table Size: 300 × 200 mm, fabricated with stainless steel

Maximum Test Piece Height: 115 mm

Illumination:

Contour Illumination: 24 V / 150 W

Surface Illumination: 12 V / 100 W

Cooling System: Vibration-free and noiseless fan motors

Accessories Included: Silicon cloth, cover-fuse bulbs, power supply cord (vinyl), and operating manual

These projectors find their applications in various fields, including automotive, aerospace, electronics, medical device manufacturing, plastics, and tool-and-die. They assist in inspecting precision components that need to conform to certain dimensions and quality standards.

The profile projector is an optical measuring instrument that magnifies and projects the silhouette of a part onto a screen. It allows operators to verify dimensions, angles, and shapes with high accuracy using non-contact measurement.

The accuracy of a profile projector varies by model but usually falls within a few microns. High-quality systems give consistent and reliable measurements that are good for very precise engineering and quality control tasks.

Profile projector price can cost about ₹49,500, while advanced systems may exceed ₹1,000,000. Factors that contribute to the variation in prices include brand, model, additional features, such as DRO, and type, either vertical or horizontal.

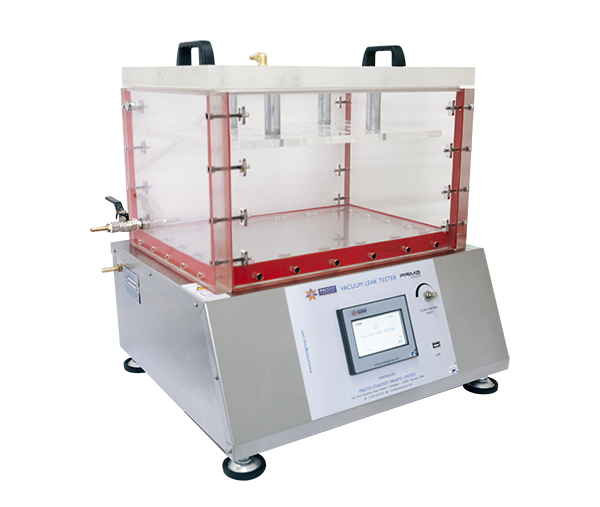

The Digital Eco Vacuum Leak Tester is an affordable and efficient solution designed to enhance quality control in packaging applications. Engineered with exceptional precision, this laboratory testing equipment accurately detects leaks in various packaging materials.

Read More

The Presto Tensile Testing Machine operates on the Constant Rate of Traverse (CRT) principle. In this test, the sample is clamped between two jaws, with the upper jaw remaining stationary while the lower jaw moves at a fixed speed controlled by a motor.

Read More

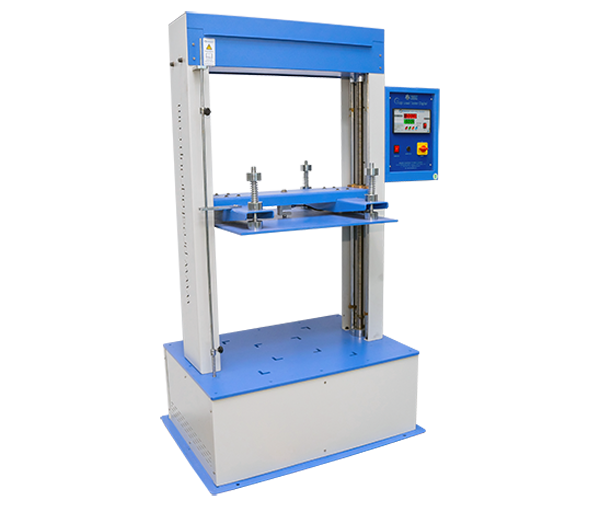

The Top Load Tester is an advanced, fully automatic motorized device designed to measure compressive buckling load in a digital format. Its digital display is not only visually appealing but also sophisticated, ensuring easy readability. Key features include an Auto Tare (ZERO) set facility and a Peak Hold arrangement.

Read More

The Secure Seal Tester is a reliable testing instrument designed to measure seal integrity in PET and plastic containers. This essential quality test ensures leak-proof bottle caps, particularly crucial in carbonated beverage production facilities.

Read More

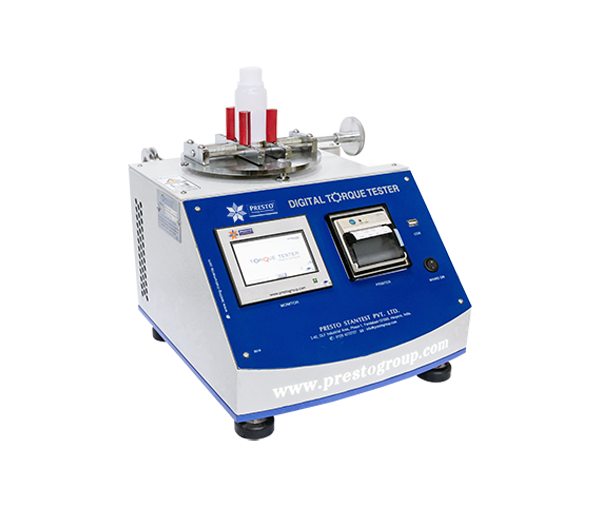

Introducing the Presto Torque Tester – HMI Touch Screen, a cutting-edge, fully automatic torque testing solution. This next-generation tester provides torque readings in digital format, offering unparalleled accuracy and convenience.

Read More

The Presto Vacuum Leak Detection System is now offered in the Prima series. Featuring an HMI touchscreen display and fully automatic controls, this system guarantees precise and repeatable results, along with comprehensive data acquisition for various tests. The vacuum tank is specifically engineered to perform leak integrity testing on large-sized packages using any testing medium.

Read More

The Vacuum Leak Tester for PET Bottles is a testing instrument designed to check the seal integrity and leak resistance of all types of PET bottles. This is perfect for use in food, medicine, beverage industries, and others where PET bottles are used for product transportation or storage.

Read More

A Vacuum Tester for Plastic Containers is a precision device used to check the sealing strength, leak resistance, and durability of plastic packaging. By creating controlled vacuum conditions, it quickly identifies weak seals, air leaks, and structural defects that could compromise product safety. Ideal for food, pharmaceutical, cosmetic, and industrial packaging, this tester ensures reliable quality control, reduces waste, and helps manufacturers meet strict industry standards.

Read More

Introducing the Presto Vacuum Leak Detection System now featured in the Prima series. Equipped with an intuitive HMI Touch Screen Display and fully automated controls, this system ensures precision with consistency while facilitating data acquisition for a variety of tests.

Read More

The Torque Tester Robo 4.0 is a high-precision, automated torque testing system designed for industrial and laboratory use. Combining advanced sensors and smart automation, it delivers accurate, reliable, and repeatable torque measurements, ensuring optimal performance, quality control, and safety across manufacturing, research, and calibration applications.

Read More

The Torque Tester Motorised: Pluto Series is a precision motorized device designed for accurate and consistent torque measurement. Ideal for quality control and research, it features automated testing, real-time digital readings, and adjustable speed control for a wide range of applications—from bottle caps and closures to mechanical and electronic components. Durable, user-friendly, and highly efficient, the Pluto Series ensures reliable results every time.

Read More

The Torque Tester – Prima Hand Operated is a precision mechanical tool designed to measure torque accurately on bolts, screws, and fasteners. Ergonomically built and fully portable, it delivers reliable readings without electricity, making it perfect for quality control, maintenance, and industrial applications. Durable, easy to use, and highly accurate.

Read More

The Top Load Tester - Digital Cum Computerized is a state-of-the-art, fully automatic motorized top load tester. It measures compressive buckling load and displays the results digitally. The high-end digital display is sophisticated and includes an Auto Tare (ZERO) set feature and a Peak Hold function. For secure gripping with no slippage, the test sample is positioned between inverted concave jaws.

Read More

Introducing the new generation Top Load Tester - Prima Series, designed specifically for PET bottles and jars. This fully automatic motorized device applies compressive buckling load to products with precision. The instrument features a Human Machine Interface (HMI) based Touchscreen display, providing easy access to compressive buckling load readings.

Read More

The Top Load Tester Digital for Jars is a precision instrument designed to measure the vertical compression strength of PET, HDPE, and glass jars. It uses advanced digital load cells and a motorized compression system to accurately determine how much top pressure a jar can withstand before deforming or collapsing. Ideal for quality control and R&D, this tester ensures packaging durability during capping, stacking, handling, and transportation.

Read More

The Secure Seal Tester – Next Generation is a cutting-edge device designed to ensure the integrity and safety of sealed products. Combining precision technology with user-friendly operation, it quickly detects weak or faulty seals, preventing leaks, contamination, and product loss. Ideal for food, pharmaceutical, cosmetic, and consumer goods industries.

Read More

The Impact Tester for Glass Bottles is a precision device designed to measure the strength and durability of glass bottles against sudden impact or shock. It delivers controlled, repeatable force to identify weak points and ensure bottles can withstand handling, transportation, and filling processes. Ideal for beverage, pharmaceutical, food, and cosmetic industries, this tester helps manufacturers improve packaging quality, reduce breakage, and meet international safety standards.

Read More

The Base clearance membrane is a lab testing instrument created after thorough research & development for the manufacturers of PET preforms & bottle industry. This testing instrument is dedicated for analyzing the depth of the containers as well as bottles. It is extremely important to determine the accurate depth of the containers & bottles to calculate the right volume of the same, and thus fill it with the respected amount.

Read More

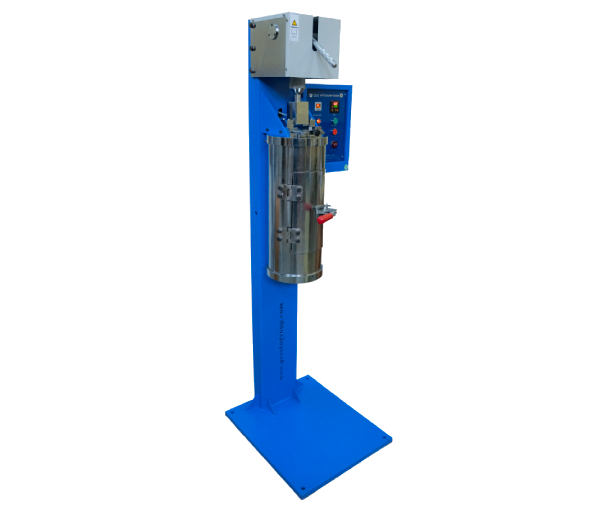

A Bottle Burst Tester – Digital is a precision instrument used to measure the pressure resistance and overall strength of PET and plastic bottles. By gradually applying controlled internal pressure, it accurately determines the burst point, helping manufacturers ensure quality, safety, and compliance with industry standards.

Read More

The touchscreen model introduces a modern approach to testing, offering smoother operation and significantly improved data visibility. Unlike traditional knob-based or analog testers, this system allows for quick adjustments, immediate result tracking, and digital recordkeeping—saving time and boosting production efficiency.

Read More

A Bottle Cap Pull-Out Tester is a precision device used to measure the force required to pull a cap off a bottle. It helps manufacturers verify sealing strength, ensure closure integrity, and maintain consistent packaging quality. By applying a controlled tensile force to the cap, the tester provides accurate pull-out force readings, making it essential for quality control in beverage, pharmaceutical, cosmetic, and chemical packaging industries.

Read More

The Cap Pull-Out Tester is a precision quality-control instrument designed to measure the force required to remove caps, lids, or closures from containers. Ideal for packaging, food & beverage, pharmaceutical, and cosmetic industries, it ensures consistent seal strength, prevents leakage, and verifies compliance with industry standards.

Read More

The G V Shaker is a durable, leak-proof bottle designed for effortless mixing of protein shakes, smoothies, and supplements. Made from high-quality, food-grade materials, it ensures smooth, clump-free drinks on the go, making it perfect for workouts, travel, or daily use.

Read More

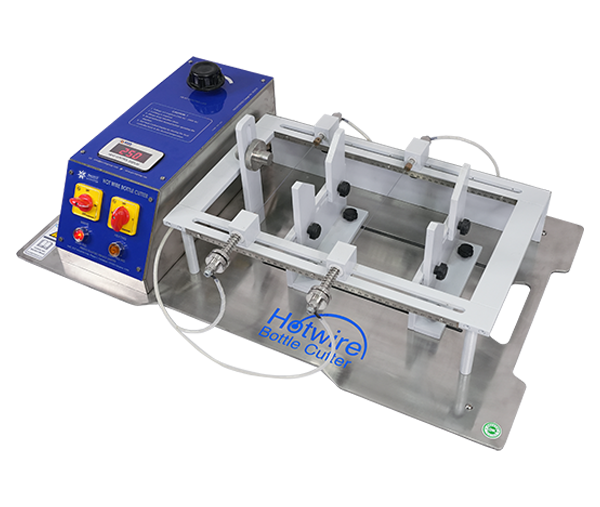

The Hot Wire Bottle Cutter - NXG is a next-generation tester designed for precise section weight analysis of PET bottles and containers. It features digital heat monitoring for accurate control.

Read More

Ensure every bottle stands perfectly upright with the Bottle Perpendicularity Tester. Designed for beverages, pharmaceuticals, cosmetics, and food industries, this precision instrument measures bottle tilt accurately and efficiently. It helps maintain quality control, reduces waste, improves shelf appeal, and ensures compliance with industry standards.

Read More

PI Tapes are precision measuring tools designed for accurate diameter measurement of cylindrical objects such as pipes, rods, and shafts. Easy to use and highly reliable, they provide direct readings with minimal error, making them ideal for engineering, manufacturing, and quality control applications.

Read More

Preform & Bottle ‘NECK’ Cutter is a precision tool designed to cleanly remove the neck portion of PET preforms and plastic bottles with accuracy and ease. Engineered for manufacturing, recycling, and quality-control applications, it delivers smooth, consistent cuts without damaging the bottle body.

Read More

Wall Thickness Gauge is a precision, non-destructive measuring tool designed to quickly and accurately determine the thickness of metals, plastics, glass, and other solid materials. Using advanced ultrasonic technology, it helps inspectors detect corrosion, wear, and structural weaknesses without damaging the surface.

Read More

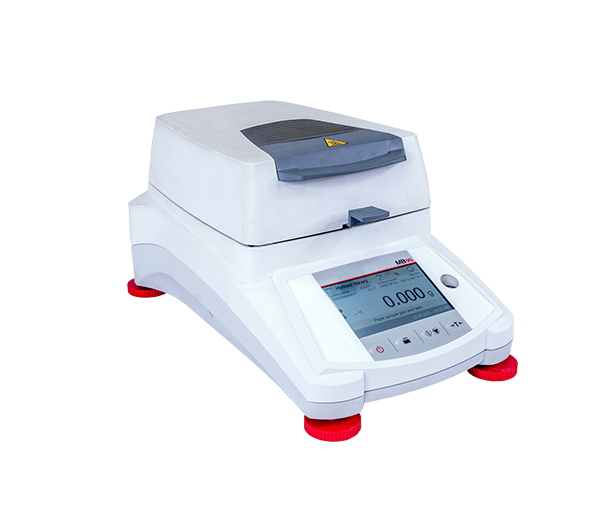

Moisture Analyzer-95 is a high-precision device for quickly determining moisture content in powders, granules, solids, and pastes. With fast, accurate results and an easy-to-use interface, it’s ideal for laboratories, quality control, and industrial applications across food, pharmaceuticals, chemicals, and agriculture.

Read More

Autoclaves and sterilizers are important machinery that are employed to kill living organisms that are harmful in the form of high-pressure steam. They offer a dependable sterilization method of medical equipment, lab materials, and other heat-resistant products that are chemical-free.

Read More

Laminar Air Flow Bench is a valuable equipment to all people in the practice who need to have a sterile and controlled working atmosphere. This bench is designed with the high cleanliness in mind, where ambient air is drawn in and run through a pre-filter and then into high-performance HEPA or ULPA filter.

Read More

The Bench Top pH/mV Meter is a high-quality laboratory device that is used to provide precise pH and millivolt readings in scientific, industrial and educational needs. It provides a stable performance with advanced calibration possibilities and easy to use interface which guarantees high-quality results during routine testing and meaningful analysis.

Read More

BOD Incubator - Prima Series is an accurate Biological Oxygen Demand (BOD) incubator and low-temperature incubator with a high degree of control. It has an advanced microprocessor control, uniform cooling and low-energy consumption operation, which require a dependable performance in environmental, microbiology, and research applications.

Read More

At Presto, we take pride in being Global manufacturers of Laboratory Testing Instruments for different industries.