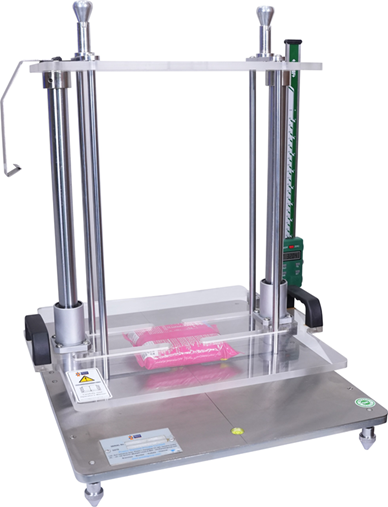

Model : HDT/VSP-500

Heat Deformation Tester is an advanced laboratory device engineered to evaluate how materials perform under high temperatures and applied loads. By determining key thermal properties such as HDT and Vicat softening temperature, this tester allows manufacturers, researchers, and quality control teams to understand the exact point at which a material begins to soften or deform.

A Heat Deformation Tester is a precision laboratory instrument used to measure how materials behave when exposed to elevated temperatures and pressure. It determines the Heat Deflection Temperature (HDT) and Vicat Softening Point (VSP)—two critical indicators of thermal performance. By applying a controlled load and gradually increasing heat, the tester reveals the temperature at which a material begins to soften, deform, or lose structural integrity. This makes it an essential tool for evaluating the reliability and durability of plastics, polymers, composites, and other heat-sensitive materials.

A Heat Deformation Tester operates by placing the specimen under a specific load and immersing it in a controlled heating medium, usually oil or silicone. As the temperature rises at a constant rate, the machine monitors the material’s deflection or softening point with high accuracy. The test ends when the specimen reaches a predefined deformation value or when the Vicat needle penetrates to the set depth.

The results provide a precise measurement of the temperature at which the material can no longer maintain its shape under stress crucial data for quality control, product design, and thermal resistance evaluation.

Presto Instruments is a leading manufacturer and supplier of Heat Deformation Tester in Tanzania For the best price, contact us for a quote or call now!

Model: HDT/VSP-500

No. of Test Stations: 2 (HDT & VSP)

Temperature Range:

Water medium: Ambient to 90°C

Silicone oil medium: Ambient to 250°C

Rate of Heating:

50 ± 5°C/hr

120 ± 10°C/hr

Temperature Controller: Digital Microprocessor PID-based with auto-tuning

Dial Gauge Range: Up to 10 mm

Least Count: 0.001 mm

Test Weights:

VSP: 10 N and 50 N

HDT: 0.455 MPa and 1.82 MPa

Indenter Tip Diameter:

HDT: 13 mm (approx.)

VSP: 1 mm (flat-ended needle)

Liquid Medium: Water (90°C) / Silicone Oil (260°C)

Heater: 1 kW × 2

Power Supply: 220V, 50Hz, Single Phase

Material Construction:

Outer Body: Mild Steel

Inner Chamber: Stainless Steel

Finish: Powder-coated Havel Gray & Blue, chrome/zinc-plated for corrosion resistance

Motor Type: Stirrer motor (1/70 HP, 1350 rpm) for uniform temperature distribution

Drain Valve: Provided

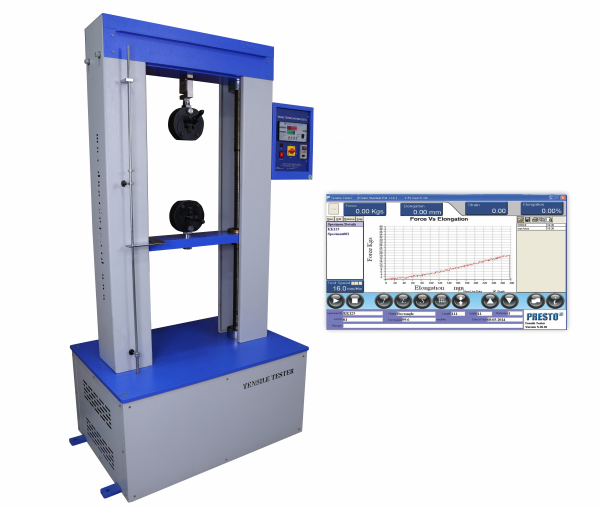

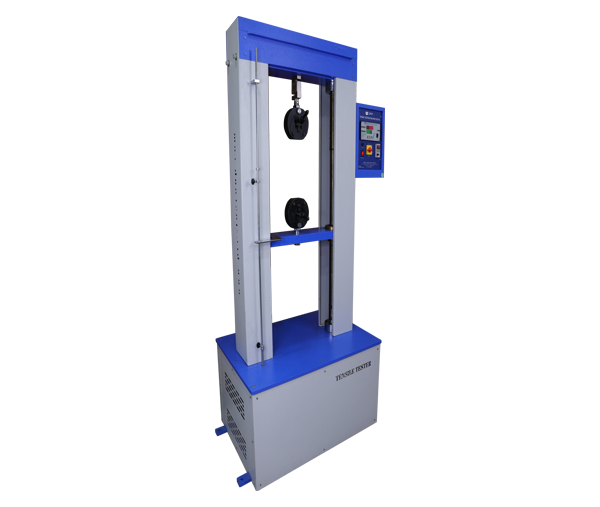

The Digital Tensile Testing Machine (Capacity: 2500KG) is a robust and precise instrument designed to measure tensile, compression, and elongation properties of materials. Featuring a digital display for accurate readings and user-friendly controls, it ensures reliable performance for quality testing in labs and industrial applications.

Read More

The Presto Melt Flow Index Tester is your go-to solution to evaluate the flow properties of molten plastics or resins. This tester is designed to measure the Melt Flow Index of thermoplastic materials and, hence, determines the rate of flow in grams per ten minutes of molten resins through a specific jet length and diameter.

Read More

A Tensile Testing Machine Digital is a precision testing instrument designed to measure the tensile strength, elongation, and other mechanical properties of various materials such as metals, polymers, rubber, textiles, and components.

Read More

The Presto Pneumatic Model Heat Sealer is a staple in the plastic industry, renowned for its versatility and reliability. Featuring adjustable temperature settings, this heat sealer is equipped with a digital display and operates on a microprocessor-based system.

Read More

The Heat Sealer Prima is a reliable tool designed for sealing flexible packaging products and thermoplastic materials by applying pressure and heat at high temperatures.

Read More

The Tensile Testing Machine (Cap.: 10000 kgf) Digital is a precision-engineered testing system designed to measure the tensile strength, elongation, and mechanical properties of various materials such as metals, plastics, rubber, and composites. Equipped with a high-accuracy digital load indicator and elongation measurement system, it provides reliable, real-time test data for quality control and research applications.

Read More

The Melt Flow Index – MFR Model offers significant benefits, including accurate testing, stable thermal control, and durable construction for long-term use. It supports industries such as injection molding, extrusion, film production, and plastic recycling, where melt flow properties directly impact product quality and production efficiency.

Read More

The Flammability Tester IS 15061 is a high-precision instrument designed to evaluate the burning resistance and flame spread properties of textiles and fabrics as per IS 15061 standards. Engineered with a stainless-steel test chamber, controlled flame system, and digital timer, it delivers accurate, repeatable results for quality control, research, and compliance testing.

Read More

The Flammability Tester for Wires and Cables is a precision testing instrument designed to evaluate the flame-retardant properties of electrical wires and cables. It measures burning behavior, flame spread, and self-extinguishing performance to ensure compliance with international safety standards like IEC, UL, ASTM, and ISO. Ideal for manufacturers, R&D labs, and quality control, it enhances product safety, reliability, and fire resistance.

Read More

The UL-94 Flammability Tester is a high-precision instrument for testing the flammability of plastic materials. It provides reliable vertical and horizontal flame testing in accordance with the UL 94 standard, making it ideal for quality control and material compliance across multiple industries.

Read More

Melt Flow Index – NEO 2.0 is a high-precision polymer testing instrument designed to measure the melt flow rate (MFR) and melt volume rate (MVR) of thermoplastics. Equipped with advanced digital controls, automatic operation, and compliance with international standards, it delivers accurate, repeatable, and reliable results for quality control, R&D, and industrial applications.

Read More

The Melt Flow Index Tester – NEO 2.0 is a high-precision instrument designed to measure the melt flow rate (MFR) of thermoplastic polymers under controlled temperature and load. Built with advanced digital controls, automated cutting, and durable construction, the NEO 2.0 ensures accurate, repeatable, and efficient testing for laboratories, research centers, and plastic manufacturing industries. It fully complies with ASTM D1238 and ISO 1133 standards.

Read More

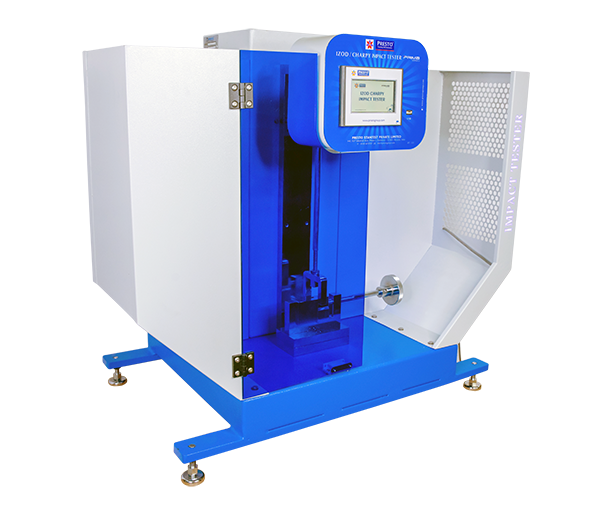

The IZOD/Charpy Impact Tester NXG Model is a high-precision, dual-mode impact testing machine engineered for accurate measurement of material toughness. With advanced sensors, robust construction, and support for international standards, it delivers fast, reliable, and repeatable results for metals, plastics, and composite materials across QC labs, manufacturing, and research environments.

Read More

The Izod / Charpy Impact Tester Computerized is a precision instrument designed to measure the impact strength and toughness of materials such as plastics, metals, and composites. Equipped with advanced sensors and automated software, it delivers accurate, repeatable Izod and Charpy test results with real-time digital analysis—ideal for laboratories, research facilities, and quality control applications.

Read More

The Izod/Charpy Impact Tester Digital is a dual-purpose instrument designed to accurately measure the impact strength of materials using both Izod and Charpy methods. Featuring a high-precision digital display and a durable pendulum system, it delivers reliable, repeatable results for quality control and laboratory testing.

Read More

The Notch Cutter Motorised Impact Tester NC 22 is a precision laboratory instrument designed for accurate and repeatable notch preparation of Charpy and Izod test specimens. Featuring motorized operation, adjustable cutting depth, and robust construction, it ensures consistent, standard-compliant notches with minimal operator effort. Ideal for quality control, research, and material testing labs, the NC 22 combines precision, safety, and ease of use in a compact, durable design.

Read More

A precision motorised notch cutter designed for Charpy and Izod impact test specimens. Ensures consistent and accurate notches, enhancing test reliability and repeatability. Features adjustable cutting depth, robust construction, and safety mechanisms, making it ideal for laboratories, quality control, and materials research.

Read More

A Flip Cap Opening Tester measures the force needed to open flip-top caps, ensuring consistent quality, ease of use, and durability in packaging. It provides accurate, repeatable results to help manufacturers verify cap performance and maintain product standards.

Read More

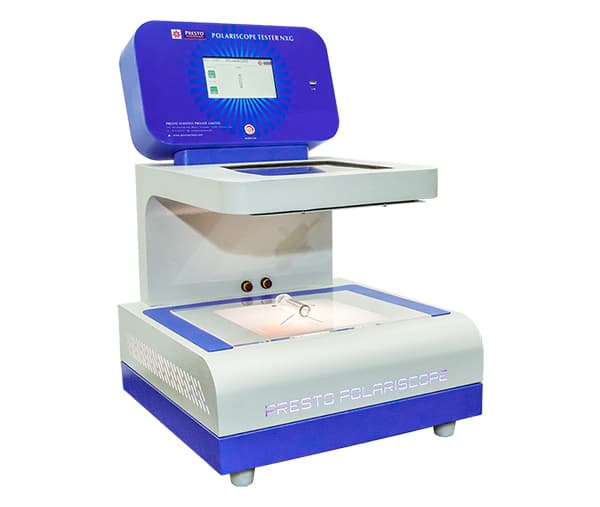

Polariscope Strain Viewer Computerised is a modern optical inspection system designed to detect and analyze internal stresses in transparent materials with high precision. Using polarized light, digital imaging, and advanced software, it provides clear visualization of strain patterns, real-time analysis, and accurate reporting.

Read More

The Polariscope-Dx for PET & Preform is a high-precision optical inspection system designed to reveal internal stresses, birefringence, and flow irregularities in PET preforms and bottles. Using polarized light and advanced illumination, it helps manufacturers optimize molding conditions, improve product strength and clarity, and reduce production defects. Ideal for PET processing plants, QA labs, and R&D departments, the Polariscope-Dx ensures c

Read More

A Tube Burst Tester is a precision instrument used to measure the internal pressure strength of tubes, hoses, and flexible packaging. It determines the exact burst point to ensure product durability, safety, and compliance with industry standards. Ideal for pharmaceuticals, cosmetics, food packaging, and industrial tubing, this tester provides accurate, reliable data for quality control and R&D applications.

Read More

The Polariscope Strain Viewer – NXG is a next-generation optical inspection device designed to reveal internal stress and birefringence in transparent materials with exceptional clarity. Featuring advanced polarized-light technology, uniform LED illumination, and an easy-to-use viewing platform, the NXG delivers fast, accurate, and non-destructive strain analysis for glass, plastics, optical parts, and molded components.

Read More

The Carbon Black Content Apparatus accurately measures the carbon black content in various materials, making it an essential tool for laboratories, R&D centers, and industrial production facilities. Its user-friendly design, fast testing capabilities, and adherence to industry standards make it the ideal choice for quality control and material analysis.

Read More

The Air Bulge Tester is a precision device used to measure the pressure strength and deformation of films, paper, and sheet materials. By applying controlled air pressure, it accurately evaluates how materials stretch, bulge, and fail, making it essential for quality control, research, and industrial testing applications.

Read More

The Carbon Black Dispersion Test Apparatus is a high-precision instrument used to assess the uniform dispersion of carbon black in rubber and polymer materials. Using advanced microscopy and standardized grading methods, it identifies particle distribution, agglomeration, and mixing quality to ensure superior material strength and consistency. Ideal for QA/QC labs, tire manufacturers, and rubber processing industries.

Read More

At Presto, we take pride in being Global manufacturers of Laboratory Testing Instruments for different industries.