Model : PPSS-2000

A peel strength tester is an analytical instrument that determines the adhesive strength of two materials brought into contact and bonded together, such as films, laminates, tapes, and labels. It measures the amount of force required to peel one material away from another under a set of controlled conditions, thereby ensuring product reliability and bond consistency. The tester works by holding the sample at both ends and applying an equal tensile force until they separate. The peak load recorded is the value of peel strength. Common in the packaging, auto, and textile industries, the Peel Strength Tester ensures that manufacturers maintain quality, confirm adhesion performance, and meet international testing standards.

A peel strength tester is a high-precision test equipment used to quantify the adhesive or bonding force of two flexible materials, e.g., laminates, tapes, or films. It measures the amount of energy needed to delaminate adhered layers under regulated conditions. The testing equipment operates based on tensile testing, which entails applying a consistent pulling force to delaminate one material from another at a given speed and angle (most commonly 180° or 90°). It aids in determining the durability, adhesion strength, and functionality of packaging and bonding materials utilized in various sectors such as packaging, automotive, and textile.

A Peel Strength Tester operates by holding the bonded test sample between two grips, of which one is fixed and the other is a moving grip. The moving grip pulls the top surface of the sample at a specified speed and at an angle (usually 180° or 90°), slowly peeling the materials apart. As peeling happens, the instrument records the force needed to remove the layers. This force is reflected as the peel strength value, which refers to the quality of the adhesive bond. The procedure allows for consistent test conditions, enabling manufacturers to check material adhesion, determine areas of poor bonding, and ensure quality levels of packaging, films, tapes, and laminated products.

Here are the benefits of the Peel Strength Tester explained in detail:

Guarantees Adhesive Quality

The Peel Strength Tester aids in identifying the bonding strength between materials, guaranteeing that adhesives, laminates, and coatings have uniform quality. Through the identification of weak bonds at an early stage, the manufacturer is able to enhance adhesion performance and avoid product failure during handling, transport, or use.

Facilitates Quality Control

Routine peel strength testing enables industries to have consistent production quality. It also makes them detect raw material variations, adhesive formulation changes, or variations in lamination processes so that each batch would meet specified performance standards and industry requirements before it is delivered to customers.

Increases Product Durability

Through the measurement of the separation force exerted to disengage bonded materials, this tester ensures that packs, films, and tapes are capable of withstanding physical stress. Adhesive bonds that are stronger mean products are more durable, reliable, and long-lasting, and can withstand different environmental and mechanical forces.

Lowers Product Failures

Peel strength testing assists in detecting the weak points of adhesion that may result in delamination or product failure. Early detection reduces rejections, fewer customer complaints, and overall product reliability—preserving defect and return cost savings in large production operations.

Here are the applications of the Peel Strength Tester explained in detail:

Packaging Industry

In the packaging industry, the Peel Strength Tester is applied to test the adhesive strength of laminated films, pouches, and sealing materials. It helps ensure seals do not open during filling, storage, and transportation, avoiding leakage or contamination of food products, drinks, and pharmaceuticals.

Adhesive Tape Manufacturing

Pressure-sensitive tape manufacturers utilize the tester to measure peel adhesion between the substrate and tape. It aids in identifying the holding power of the tape, maintaining uniform stickiness, easy removal without any residue, and consistent performance on various surfaces and environments.

Label and Sticker Industry

The tester assists in verifying the stickiness of printed labels and stickers on different packaging materials. It keeps labels securely in place even under humidity, temperature shift, or manipulation, ensuring product identification, branding, and compliance details stay intact throughout the supply chain.

Automotive Industry

In the vehicle industry, it is applied to check the adhesion of interior trims, protective films, and insulating materials. It helps ensure adhesive joints and coatings are securely fastened under vibration, heat, and pressure, leading to long-term durability and vehicle safety standards.

Presto Instruments Peel Strength Tester is engineered for high precision, reliability, and consistent performance. It is equipped with a precise load cell and digital readout to provide consistent peel strength measurements for tapes, films, and laminates. The equipment provides variable speeds, adjustable angles, and simple operation for international testing standard compliance. Its tough body, in-house calibration lab, and sophisticated data recording render it perfect for industries and labs looking to achieve high adhesive quality with strong bonding performance.

Presto Instruments is a leading manufacturer and supplier of Peel Adhesion Bond Seal Strength Tester in Malaysia. For the best price, contact us for a quote or call now!

Key Specification :

|

Load Cell Capacity |

100 Kgf |

|

Display |

LED (Digital) 7 segment |

|

Accuracy |

± 1% at full load (with master load) |

|

Least Count/Resolution |

0.020 Kgf |

|

Power |

220V , Single phase, 50 Hz |

|

Test Speed | 300 mm/min± 5% |

|

Memory |

After perform the test max. value save in memory |

|

Grip Separation | Min. 25 mm & Max. 300 mm |

Highlights :

|

Safety Switch |

Yes |

|

Material |

Mild Steel |

|

Finish |

Powder coated Havel Gray & Blue combination finish and bright chrome / zinc plating for corrosion resistant finish |

| Dimensions | 600x500x1120 mm |

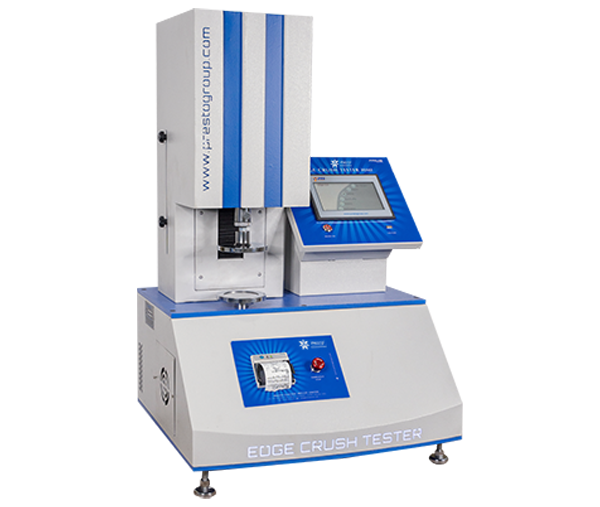

The RCT/FCT/Edge Crush Tester is a reliable tool designed to measure the crush strength of cardboard boxes and packaging containers. This instrument assesses the crushing resistance in units of Kg per unit length, providing essential data for ensuring packaging durability.

Read More

A drop tester is a device used to evaluate a product’s durability by simulating real-world drops and impacts. It helps assess structural integrity, packaging performance, and overall resilience under controlled test conditions.

Read More

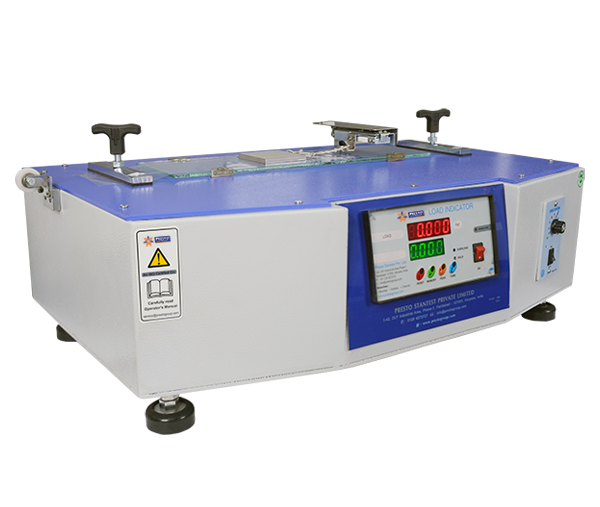

We all know that friction testing is considered to be a crucial aspect of quality control, especially in the case of flexible packaging films. The co-efficient of packaging can significantly impact how easily the package will slide or move during transit. A low COF can cause the package to slide too easily, risking damage to its contents. Conversely, a high COF can make the package difficult to handle, potentially causing delays.

Read More

The Digital Pneumatic Bursting Strength Tester is equipped with a digital display and pneumatic clamping system, enabling the determination of bursting strength for various materials such as paper, paperboard, solid fiberboard, and corrugated board and boxes. This equipment is highly valued for its ability to deliver fast and accurate test results, consolidating multiple functionalities into a single instrument.

Read More

The box compression tester digital mini is a paradigm of technology advancement by the Presto Group. The instrument is created to help the manufacturers of small corrugated boxes used for packaging purposes in the bakery industry, minimal accessory industry, etc.

Read More

Scuffing refers to the abrasion that occurs when two materials rub against each other. The Scuff Resistance Tester is an essential tool for assessing the rub resistance, or damage caused by rubbing, of labels and various printed materials.

Read More

The Dart Impact Tester Robo 2.0 is more than just a testing device—it is a comprehensive solution for evaluating the strength, durability, and quality of materials under impact conditions. Equipped with a robust frame, intelligent software, and precision mechanics, the Robo 2.0 ensures repeatable results that comply with international testing standards.

Read More

At Presto, we take pride in being Global manufacturers of Laboratory Testing Instruments for different industries.