Model : 0130 (150 mm)

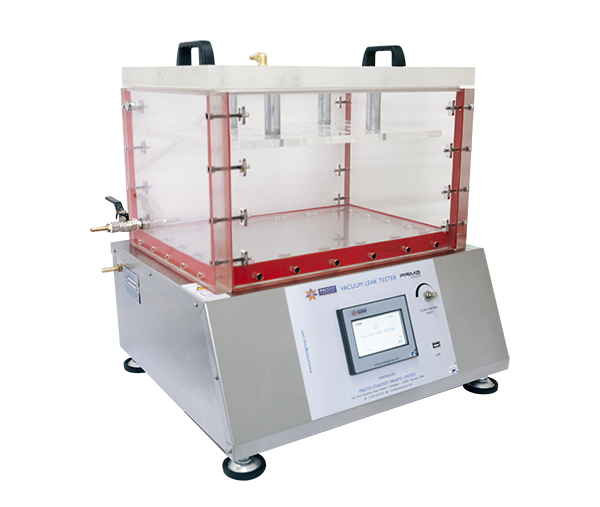

A vacuum leak tester is a sophisticated quality control instrument that is utilized to assess the sealing integrity and performance of sealed products, components, pipelines, and assemblies. The device accomplishes this by creating a controlled vacuum in the test chamber or system and measuring the pressure fluctuations over time. Once the vacuum system is engaged, an increase in air or gas is detected by the increase in pressure in the system. Minor increases in vacuum would identify a possible defect in the sealed test specimen. The vacuum leak test method is applicable for various industries, particularly where the air-tightness of products in packaging or the reliability of systems is critical.

A vacuum leak tester is a highly accurate testing tool that determines sealing integrity, components, products, and packing by measuring the occurrence of leaks. The vacuum decay principle is employed by the tester that generates a vacuum in a test chamber or sample and monitors pressure variations with time. In many cases, if pressure rises, then it's an indication of air or gas leaking from the sample.

Leak testing with a vacuum decay is a non-destructive testing method that provides product assurance and an airtight seal. Leak testing with a vacuum decay principle is a necessary testing methodology that is highly respected in leak testing standards as well as industries (packaging, automotive, pharmaceuticals, electronics) that require the assurance of leak-proof performance with quality sealing.

A vacuum leak tester operates on the principle of developing a vacuum inside a sealed chamber with the test sample inside. After attaining the desired vacuum, the system is sealed, and the pressure is noted for a given time. If the pressure remains unchanged, then the sample is leak-free; any increase in pressure, however, indicates a leak because air or gas has diffused into the chamber. This process is part of the vacuum decay technique, which allows for non-destructive and quantitative detection of leaks, even those so small as to be undetectable visually or by feel, so that the product can be assured to be sealed or package integrity and product quality fit for many industrial uses.

Precise Leak Detection:

The vacuum leakage tester provides highly accurate results and is capable of detecting very small leaks, which would not easily be found by standard methods. Accurate results provide assurance of outstanding product quality, preventing defects and ensuring the integrity of sealed systems in situations such as packaging, automotive, and pharmaceuticals.

Non-Destructive Testing:

The vacuum leak test does not destroy or otherwise damage the test sample, unlike destructive testing methods. The product remains functional and verified for sealability, and is therefore ideal for quality control processes requiring the original state of components and packaging to remain intact.

Increased Product Reliability:

Vacuum leak testers enhance product life and reliability through impermeable sealing and the reduction of leakage risks. The end result is the improved product performance, lower failure rates during transport or in storage, and increased customer satisfaction when safety and accuracy are everything.

Simple to Use and Quick Results:

Vacuum leak testers incorporate easy-to-use interfaces and automated processes that reduce complicated testing methods. The vacuum leak testers generate quick, repeatable results using a minimal amount of time and effort to improve and assure quality control testing standards when testing multiple samples or batches of production.

Affordable Quality Control

Utilizing vacuum leak testing decreases product rejections, minimizes material waste, and avoids avoidable costly recalls. Its validity and precision help save money and maintain costly quality assurance criteria for manufacturers and regulatory compliance for long-term savings.

Packaging Integrity Testing:

Vacuum leak testers are widely used in testing packaging airtightness of food, pharmaceuticals, and medical devices. Leak detection is critical for ensuring product safety, increasing shelf life, and preventing contamination, which is a key step in quality control for consumer and industrial applications.

Automotive Component Testing:

Vacuum leak testers also provide airtight sealing tests for automotive applications. They measure the sealing of fuel systems, radiators, hoses, and other components. Early leak detection helps prevent failures, improve vehicle safety, and help comply with industry regulations for performance and durability over a wide range of operating conditions.

Electronics and Semiconductor Testing:

Vacuum leak testing is used to test the hermetic sealing of electronic enclosures, sensors, and semiconductor packaging. It will prevent moisture ingress, protect sensitive circuitry, and ensure device reliability, particularly where high-accuracy electronics are used in sectors such as aerospace, medical devices, and plant automation.

Pipework and Assembly Testing:

The test is used to test the integrity of piping or valve assembly with complicated structural systems. Through leaks in pressure or vacuum systems, the manufacturers achieve safe operation, reduced fluid loss and reduced risk to the environment, specifically in the chemicals, oil and gas sectors.

The Vacuum Leak Tester from Presto Instruments offers accurate, fast, and reliable detection of leaks in a variety of industrial applications. Using sophisticated vacuum decay-based technology, it can accurately detect even the tiniest leaks without compromising the integrity of the test sample. The easy-to-use features of the product, quick testing cycle times, and the ability to integrate with other automation make the test process simpler and more effective for quality control processes. Designed to be tough and dependable in performance, this leak detector represents a great solution for packaging, automotive, medical, and/or electronics industries. Presto Instruments offers added value to any user looking to provide additional confidence in product reliability, meet standards in the industry, and ensure the highest quality sealing integrity in even the most critical applications.

Presto Instruments is a leading manufacturer and supplier of Vacuum Leak Tester Digital-ECO in UAE. For the best price, contact us for a quote or call now!

To Know more about information visit- Vacuum Leak Tester

A vacuum leak test machine is a device used to check whether a product or package is properly sealed. By creating a vacuum around the item, the machine can detect if air or fluid escapes, indicating a leak. It's a widely used method in industries like packaging, food, pharmaceuticals, and automotive.

A vacuum leak tester works by placing a product in a sealed chamber and removing the air to create a vacuum. If the item has any leakage, bubbles or pressure changes are observed during the test. This makes it a reliable and non-destructive way to check package integrity.

Yes, there is. A dry vacuum leak tester doesn't use water and is ideal for products that can't get wet, such as electronics or dry packaging. A wet vacuum leak tester, on the other hand, uses water to visibly detect bubbles from any leaks, and is commonly used for sealed bottles or pouches.

The vacuum leak tester price can vary depending on the features, model, and whether it’s a manual or digital unit. Basic manual testers may start from a few hundred dollars, while advanced digital systems with automation can cost significantly more. Always consult with a vacuum leak tester manufacturer to get a model that fits your needs and budget.

Absolutely. A vacuum leak tester for bottles is specifically designed to check if bottle caps or seals are secure. It ensures that no air or liquid can escape, which is crucial for beverages, pharmaceuticals, and chemical products.

The UAE is a rapidly growing manufacturing, and packaging industry, but it still faces the challenge of maintaining high-quality standards to fulfill both local and global demands. Unreliability of testing equipment like digital top load testers in UAE can lead to unsuccessful deliveries of subpar packaging, that would damage the product during transit.

Read More

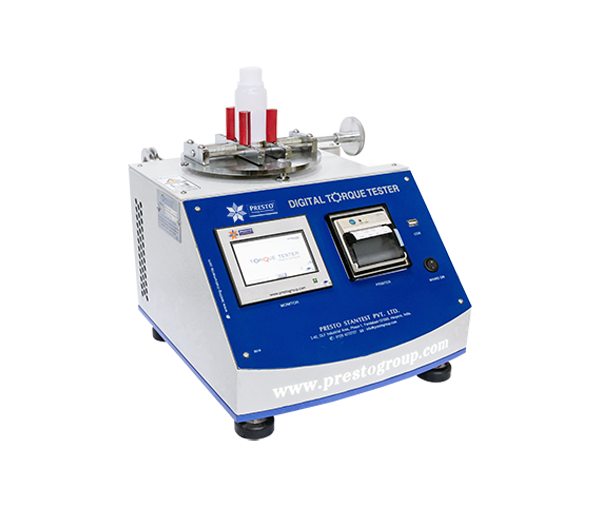

Introducing the Presto Torque Tester – HMI Touch Screen, a cutting-edge, fully automatic torque testing solution. This next-generation tester provides torque readings in digital format, offering unparalleled accuracy and convenience.

Read More

Wall Thickness Gauge is a precision, non-destructive measuring tool designed to quickly and accurately determine the thickness of metals, plastics, glass, and other solid materials. Using advanced ultrasonic technology, it helps inspectors detect corrosion, wear, and structural weaknesses without damaging the surface.

Read More

The Presto Tensile Testing Machine operates on the Constant Rate of Traverse (CRT) principle. In this test, the sample is clamped between two jaws, with the upper jaw remaining stationary while the lower jaw moves at a fixed speed controlled by a motor.

Read More

The Secure Seal Tester is a reliable testing instrument designed to measure seal integrity in PET and plastic containers. This essential quality test ensures leak-proof bottle caps, particularly crucial in carbonated beverage production facilities.

Read More

The Presto Vacuum Leak Detection System is now offered in the Prima series. Featuring an HMI touchscreen display and fully automatic controls, this system guarantees precise and repeatable results, along with comprehensive data acquisition for various tests. The vacuum tank is specifically engineered to perform leak integrity testing on large-sized packages using any testing medium.

Read More

The Vacuum Leak Tester for PET Bottles is a testing instrument designed to check the seal integrity and leak resistance of all types of PET bottles. This is perfect for use in food, medicine, beverage industries, and others where PET bottles are used for product transportation or storage.

Read More

A Vacuum Tester for Plastic Containers is a precision device used to check the sealing strength, leak resistance, and durability of plastic packaging. By creating controlled vacuum conditions, it quickly identifies weak seals, air leaks, and structural defects that could compromise product safety. Ideal for food, pharmaceutical, cosmetic, and industrial packaging, this tester ensures reliable quality control, reduces waste, and helps manufacturers meet strict industry standards.

Read More

Introducing the Presto Vacuum Leak Detection System now featured in the Prima series. Equipped with an intuitive HMI Touch Screen Display and fully automated controls, this system ensures precision with consistency while facilitating data acquisition for a variety of tests.

Read More

The Torque Tester Robo 4.0 is a high-precision, automated torque testing system designed for industrial and laboratory use. Combining advanced sensors and smart automation, it delivers accurate, reliable, and repeatable torque measurements, ensuring optimal performance, quality control, and safety across manufacturing, research, and calibration applications.

Read More

The Torque Tester Motorised: Pluto Series is a precision motorized device designed for accurate and consistent torque measurement. Ideal for quality control and research, it features automated testing, real-time digital readings, and adjustable speed control for a wide range of applications—from bottle caps and closures to mechanical and electronic components. Durable, user-friendly, and highly efficient, the Pluto Series ensures reliable results every time.

Read More

The Torque Tester – Prima Hand Operated is a precision mechanical tool designed to measure torque accurately on bolts, screws, and fasteners. Ergonomically built and fully portable, it delivers reliable readings without electricity, making it perfect for quality control, maintenance, and industrial applications. Durable, easy to use, and highly accurate.

Read More

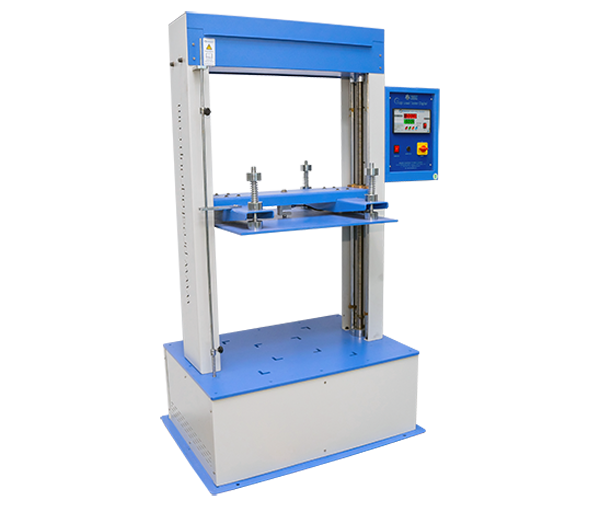

The Top Load Tester - Digital Cum Computerized is a state-of-the-art, fully automatic motorized top load tester. It measures compressive buckling load and displays the results digitally. The high-end digital display is sophisticated and includes an Auto Tare (ZERO) set feature and a Peak Hold function. For secure gripping with no slippage, the test sample is positioned between inverted concave jaws.

Read More

Introducing the new generation Top Load Tester - Prima Series, designed specifically for PET bottles and jars. This fully automatic motorized device applies compressive buckling load to products with precision. The instrument features a Human Machine Interface (HMI) based Touchscreen display, providing easy access to compressive buckling load readings.

Read More

The Top Load Tester Digital for Jars is a precision instrument designed to measure the vertical compression strength of PET, HDPE, and glass jars. It uses advanced digital load cells and a motorized compression system to accurately determine how much top pressure a jar can withstand before deforming or collapsing. Ideal for quality control and R&D, this tester ensures packaging durability during capping, stacking, handling, and transportation.

Read More

The Secure Seal Tester – Next Generation is a cutting-edge device designed to ensure the integrity and safety of sealed products. Combining precision technology with user-friendly operation, it quickly detects weak or faulty seals, preventing leaks, contamination, and product loss. Ideal for food, pharmaceutical, cosmetic, and consumer goods industries.

Read More

A Digital Profile Projector is an advanced optical measuring instrument used to inspect and measure small mechanical parts with high precision. It projects the enlarged profile of an object onto a screen and provides accurate digital measurements of dimensions, angles, and contours. Widely used in manufacturing, automotive, aerospace, and tool-making industries, it ensures quality control and precise component analysis.

Read More

The Impact Tester for Glass Bottles is a precision device designed to measure the strength and durability of glass bottles against sudden impact or shock. It delivers controlled, repeatable force to identify weak points and ensure bottles can withstand handling, transportation, and filling processes. Ideal for beverage, pharmaceutical, food, and cosmetic industries, this tester helps manufacturers improve packaging quality, reduce breakage, and meet international safety standards.

Read More

The Base clearance membrane is a lab testing instrument created after thorough research & development for the manufacturers of PET preforms & bottle industry. This testing instrument is dedicated for analyzing the depth of the containers as well as bottles. It is extremely important to determine the accurate depth of the containers & bottles to calculate the right volume of the same, and thus fill it with the respected amount.

Read More

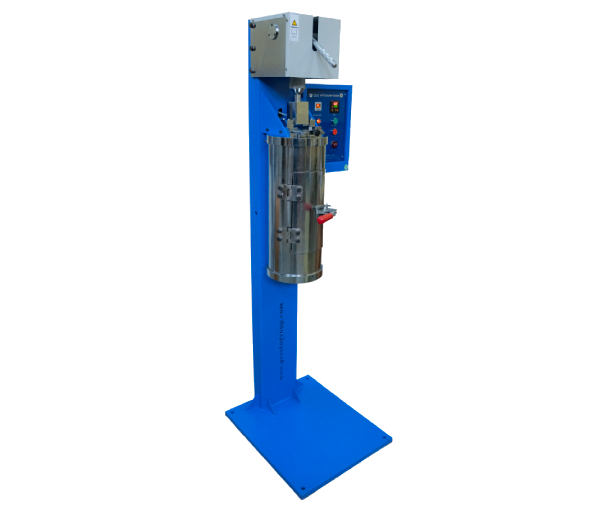

A Bottle Burst Tester – Digital is a precision instrument used to measure the pressure resistance and overall strength of PET and plastic bottles. By gradually applying controlled internal pressure, it accurately determines the burst point, helping manufacturers ensure quality, safety, and compliance with industry standards.

Read More

The touchscreen model introduces a modern approach to testing, offering smoother operation and significantly improved data visibility. Unlike traditional knob-based or analog testers, this system allows for quick adjustments, immediate result tracking, and digital recordkeeping—saving time and boosting production efficiency.

Read More

A Bottle Cap Pull-Out Tester is a precision device used to measure the force required to pull a cap off a bottle. It helps manufacturers verify sealing strength, ensure closure integrity, and maintain consistent packaging quality. By applying a controlled tensile force to the cap, the tester provides accurate pull-out force readings, making it essential for quality control in beverage, pharmaceutical, cosmetic, and chemical packaging industries.

Read More

The Cap Pull-Out Tester is a precision quality-control instrument designed to measure the force required to remove caps, lids, or closures from containers. Ideal for packaging, food & beverage, pharmaceutical, and cosmetic industries, it ensures consistent seal strength, prevents leakage, and verifies compliance with industry standards.

Read More

The G V Shaker is a durable, leak-proof bottle designed for effortless mixing of protein shakes, smoothies, and supplements. Made from high-quality, food-grade materials, it ensures smooth, clump-free drinks on the go, making it perfect for workouts, travel, or daily use.

Read More

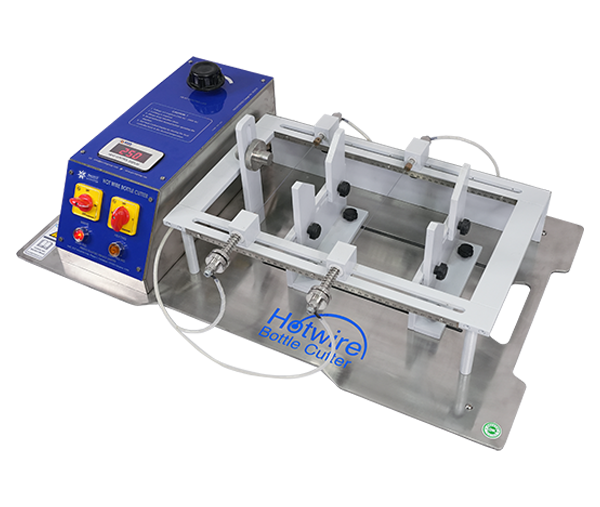

The Hot Wire Bottle Cutter - NXG is a next-generation tester designed for precise section weight analysis of PET bottles and containers. It features digital heat monitoring for accurate control.

Read More

Ensure every bottle stands perfectly upright with the Bottle Perpendicularity Tester. Designed for beverages, pharmaceuticals, cosmetics, and food industries, this precision instrument measures bottle tilt accurately and efficiently. It helps maintain quality control, reduces waste, improves shelf appeal, and ensures compliance with industry standards.

Read More

PI Tapes are precision measuring tools designed for accurate diameter measurement of cylindrical objects such as pipes, rods, and shafts. Easy to use and highly reliable, they provide direct readings with minimal error, making them ideal for engineering, manufacturing, and quality control applications.

Read More

Preform & Bottle ‘NECK’ Cutter is a precision tool designed to cleanly remove the neck portion of PET preforms and plastic bottles with accuracy and ease. Engineered for manufacturing, recycling, and quality-control applications, it delivers smooth, consistent cuts without damaging the bottle body.

Read More

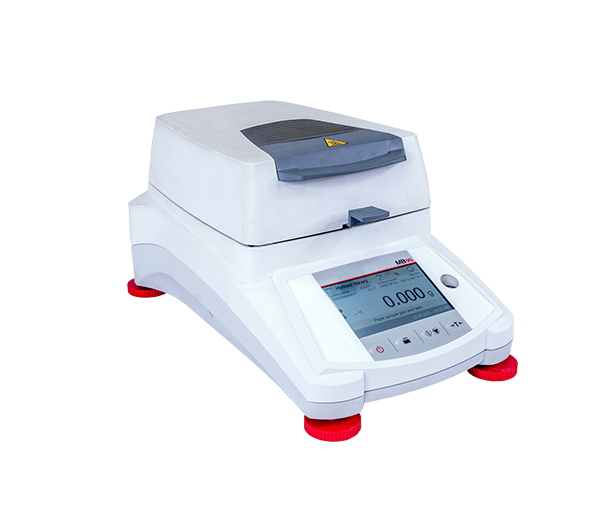

Moisture Analyzer-95 is a high-precision device for quickly determining moisture content in powders, granules, solids, and pastes. With fast, accurate results and an easy-to-use interface, it’s ideal for laboratories, quality control, and industrial applications across food, pharmaceuticals, chemicals, and agriculture.

Read More

Autoclaves and sterilizers are important machinery that are employed to kill living organisms that are harmful in the form of high-pressure steam. They offer a dependable sterilization method of medical equipment, lab materials, and other heat-resistant products that are chemical-free.

Read More

Laminar Air Flow Bench is a valuable equipment to all people in the practice who need to have a sterile and controlled working atmosphere. This bench is designed with the high cleanliness in mind, where ambient air is drawn in and run through a pre-filter and then into high-performance HEPA or ULPA filter.

Read More

The Bench Top pH/mV Meter is a high-quality laboratory device that is used to provide precise pH and millivolt readings in scientific, industrial and educational needs. It provides a stable performance with advanced calibration possibilities and easy to use interface which guarantees high-quality results during routine testing and meaningful analysis.

Read More

BOD Incubator - Prima Series is an accurate Biological Oxygen Demand (BOD) incubator and low-temperature incubator with a high degree of control. It has an advanced microprocessor control, uniform cooling and low-energy consumption operation, which require a dependable performance in environmental, microbiology, and research applications.

Read More

At Presto, we take pride in being Global manufacturers of Laboratory Testing Instruments for different industries.