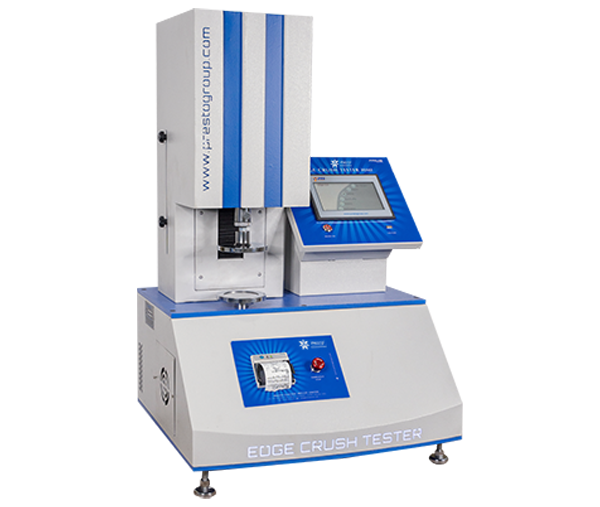

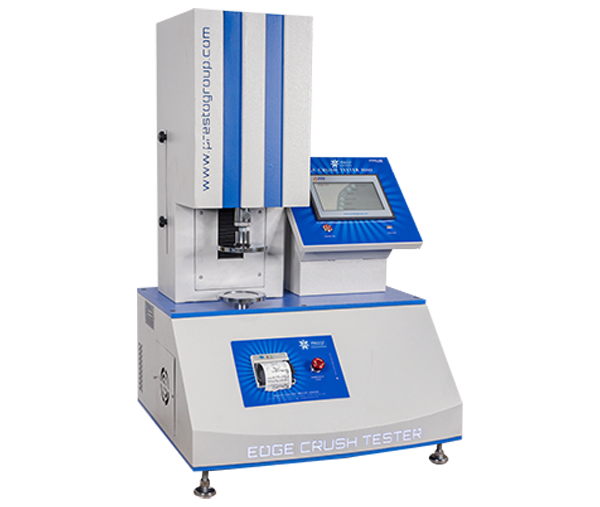

A device called an Edge Crush Tester (ECT) is utilized to assess the edgewise compressive strength of corrugated boards, while also helping to determine stacking strength and durability. It evaluates how much stress the material can sustain before it bows, when you measure and apply so much stress on the edge of the corrugated material to determine maximum compressive strength. The test ensures that the packaging boxes that manufacturers produce have adequate strength that protect the contents from rough handling in storage and transit. In addition, the ECT value is useful in determining the handling capacity of the box, making it an essential tool for quality control in the packaging sector.

An Edge Crush Tester (ECT) is a high-quality testing device used to assess the edgewise compressive strength of corrugated boxes and boards. Testing with the ECT helps determine a material's resistance to crushing when pressure is applied vertically, a need-to-know measurement when assessing the stacking strength of packaging. Using the principles of compression, the tester applies force perpendicular to the edge of a sample of corrugated box board until the material crushes. The highest load sustained is the material's edge crush strength, assuring uniformity of the packaging’s use.

An Edge Crush Tester will exert a controlled compressive force on the edge of a corrugated board test specimen between two rigid plates. The test specimen is loaded perpendicular to the surface of loading to represent the actual conditions of stacking. With plates closing together, pressure is incrementally increased until the test specimen breaks. Next, the tester measures the greatest force when the sample fails, also known as the Edge Crush Test (ECT) value. ECT is a measure of the board's stacking strength and helps manufacturers design packaging that will be resilient to handling, storage, and transportation without damage.

Here are the benefits of the Edge Crush Tester explained in detail:

Guarantees Packaging Strength

The Edge Crush Tester evaluates the compressive durability of corrugated boxes to protect them from stacking loads through transport and storage. By verifying edgewise strength, manufacturers can ensure that all packaging materials are durable enough to prevent goods from crushing and deforming under excessive load.

Improves Quality Control

Manufacturers can ensure consistent product quality from the results of frequent edge crush tests. It allows them to recognize weak points in corrugated materials before manufacturing in mass quantities, ensuring only quality boards are used. This alone can help reduce loss of product, consumer returns, and loss of profits due to package failure.

Maximizes Material Use

The Edge Crush Tester maximizes raw material utilization by accurately measuring board strength requirements for specific applications. This enables manufacturers to find the most appropriate cost/performance balance, minimizing material waste, and still producing boxes with sufficient load-bearing ability for safe carrying and storage.

Enhances Customer Satisfaction

Better and more durable packaging guarantees that products arrive with customers in pristine condition. Through the application of an Edge Crush Tester, companies can create boxes with maximum strength, reducing the risk of damage during handling and shipping, thus enhancing brand image and customer satisfaction, and trust.

Here are the applications of the Edge Crush Tester, explained in detail:

Corrugated Box Production

When corrugated boxes are produced, one tests the edgewise board strength prior to conversion to boxes using an Edge Crush Tester. This guarantees that only material with adequate compressive strength is used, resulting in strong boxes capable of withstanding stacking and transportation forces.

Paper and Packaging Industry

The tester finds extensive application within the paper and packaging industry to analyze the performance of corrugated sheets and paperboards. It assists manufacturers in identifying the right materials for various packaging requirements, providing durability, cost-effectiveness, and adherence to quality standards.

Quality Assurance Laboratories

Edge Crush Testers are valuable pieces of equipment found in many quality control laboratories performing routine testing and control on packaging material. They help in identifying differences in material quality to ensure that every batch of corrugated board produced meets internal, industry and customer specifications before packaging production.

Transportation and Logistics

In logistics, the Edge Crush Tester helps design boxes that can withstand stacking loads and vibrations during transport. It helps boxes retain their structure during transport to avoid product damage and reduce financial losses due to crushed or deformed boxes.

Presto Instruments Edge Crush Tester is built with precision and ruggedness to provide precise and consistent test results. It has highly-rated load sensors, a user-friendly interface, and solid construction for long-lasting durability. The tester conforms to international test standards and is perfect for the packaging and paper industries. Presto's technical support, calibration, and years of experience make it a sure bet for packaging strength, product safety, and quality control.

Presto Instruments is a leading manufacturer and supplier of Edge Crush Tester (RCT/ ECT /FCT) Digital in Sri-Lanka. For the best price, contact us for a quote or call now!

Key Specification :

|

Load Cell Capacity |

100 Kgf |

|

Display |

LED (Digital) |

|

Accuracy |

±2% at full load (with master load) |

|

Least Count/Resolution |

0.01 Kg |

|

Power |

220V, Single phase, 50 Hz |

|

Test Speed |

12.5± 2.5 mm/min . |

Highlights :

|

Safety Switch |

Upward & Downward Limit Switches |

|

Material |

Mild Steel |

|

Finish |

Powder coated Havel Gray & Blue combination finish and bright chrome / zinc plating for corrosion resistant finish |

|

Dimensions |

600x500x863 mm |

It executes the test for edge crush, ring crush, and flat crush so that packaging can be assessed concerning durability.

Its functionality ensures that materials withstand stacking pressures, which makes the possibility of transit damage less.

Yes, the use of feather-touch controls combined with a bright LED makes the operation intuitive.

Yes, it is designed to ensure global testing standards are satisfied.

Presto delivers precision, toughness, and industrial knowledge supported by over 40 years of experience.

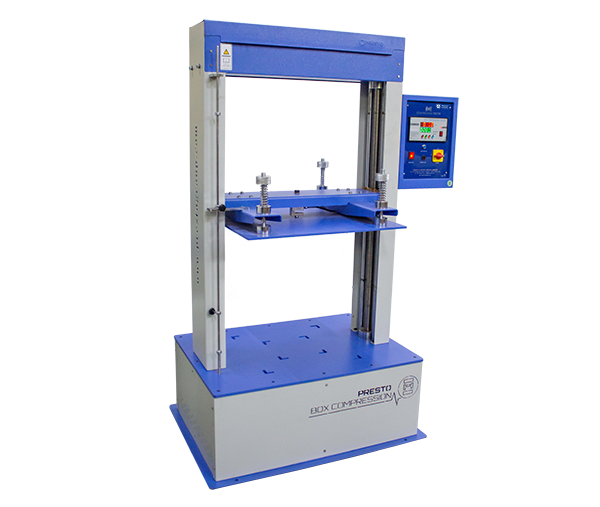

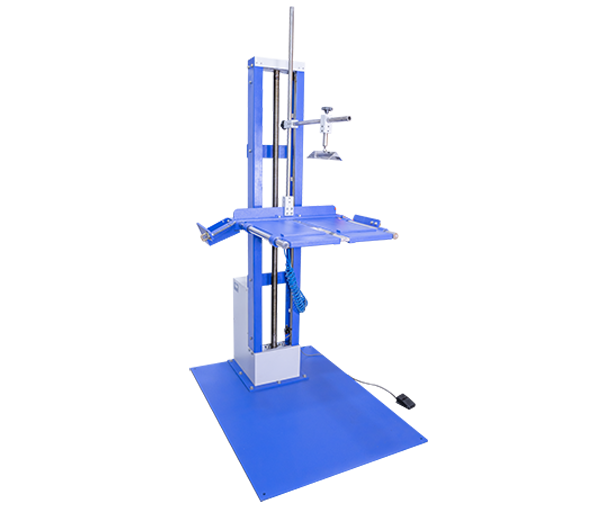

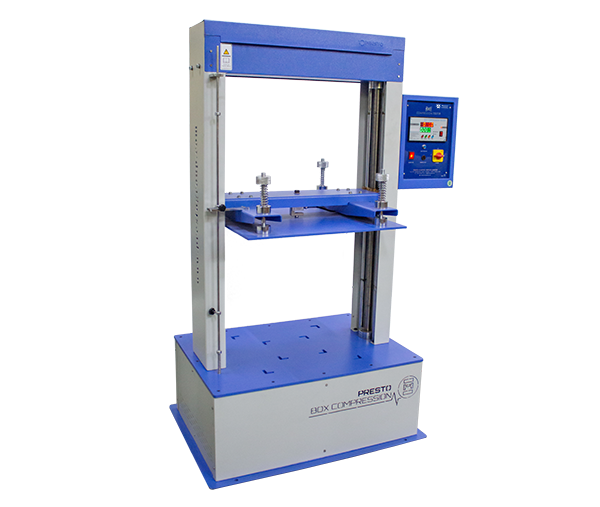

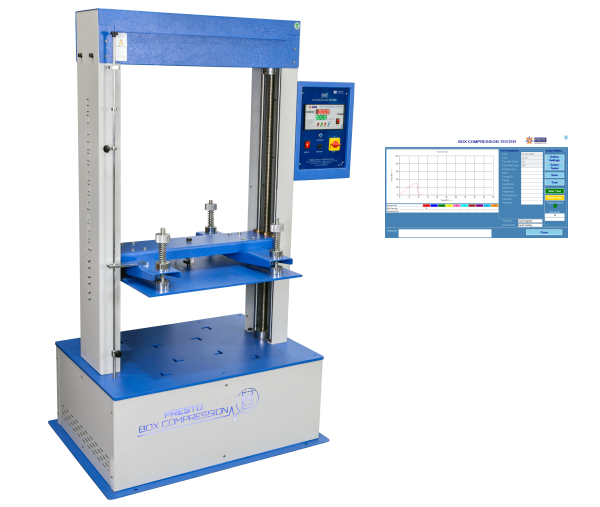

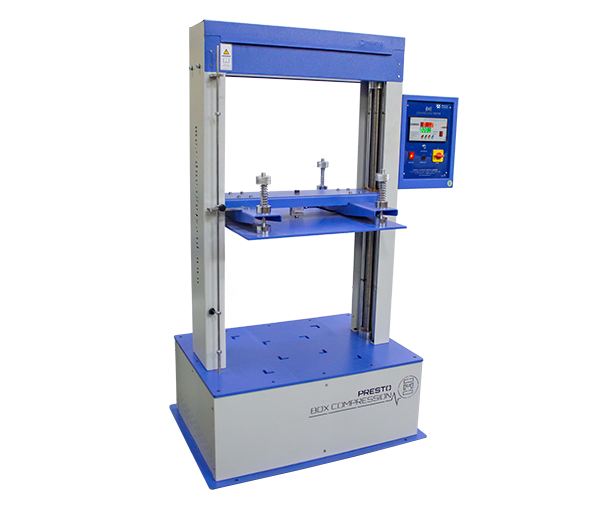

The box compression tester is a lab testing instrument designed by the Presto with precision to assess the ability of corrugated boxes to withstand compression. The test is performed by forcing downward pressure on the corrugated box through a motorized platform connected through the circular lead screws for smooth movement.

Read More

In the booming packaging and paper industries in Sri Lanka, ensuring that the paper, paperboard, and other raw materials are strong and do not break easily is of paramount importance. The improper equipment for testing would likely put the manufacturers at risk of producing inferior goods, which may not come up to the desired level of quality.

Read More

A drop tester is a device used to evaluate a product’s durability by simulating real-world drops and impacts. It helps assess structural integrity, packaging performance, and overall resilience under controlled test conditions.

Read More

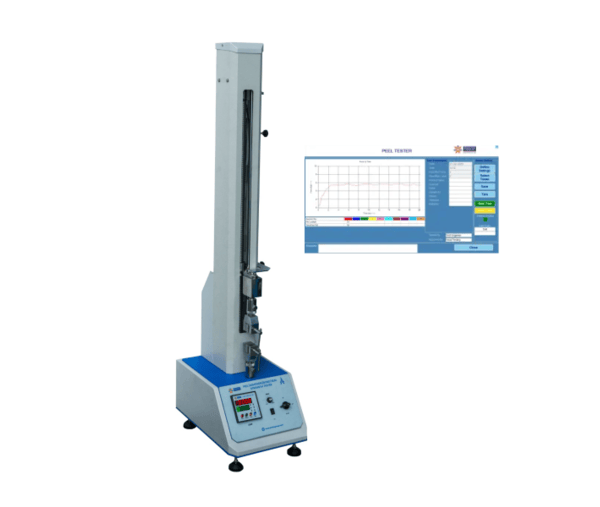

The Peel Tester Computerised Cum Digital is a high-precision testing machine used to measure the peel, bond, and adhesion strength of laminated, sealed, or bonded materials. Designed with advanced digital controls and computer-based software, it provides accurate, consistent, and real-time data for quality assurance.

Read More

Durability is key to competitive packaging and labeling industries such as Sri Lanka's. Companies run the risk of delivering products with smudged or faded labels by not using a Scuff Resistance Tester. Product presentation and, thereby, brand reputation would suffer due to this. A disappointed customer will reduce shelf appeal, and subsequently, affect sales.

Read More

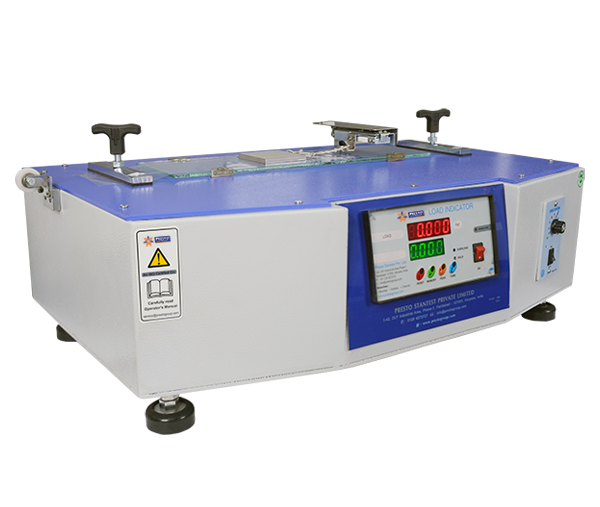

In the packaging, plastics, and textiles industries, the right surface friction is very important. Without a Coefficient of Friction (COF) Tester in Sri Lanka, especially a digital model, manufacturers in Sri Lanka risk having products that are inconsistent, of lower quality control, and do not meet international standards.

Read More

The RCT/FCT/Edge Crush Tester is a reliable tool designed to measure the crush strength of cardboard boxes and packaging containers. This instrument assesses the crushing resistance in units of Kg per unit length, providing essential data for ensuring packaging durability.

Read More

A precision digital instrument designed to measure the peel, bond, and seal strength of adhesives, laminates, films, tapes, and packaging materials. It provides accurate, repeatable force measurements with user-friendly controls, ideal for quality control, R&D, and material performance testing.

Read More

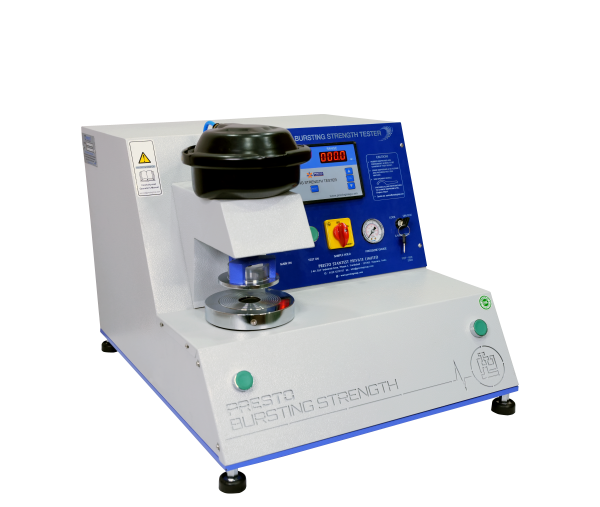

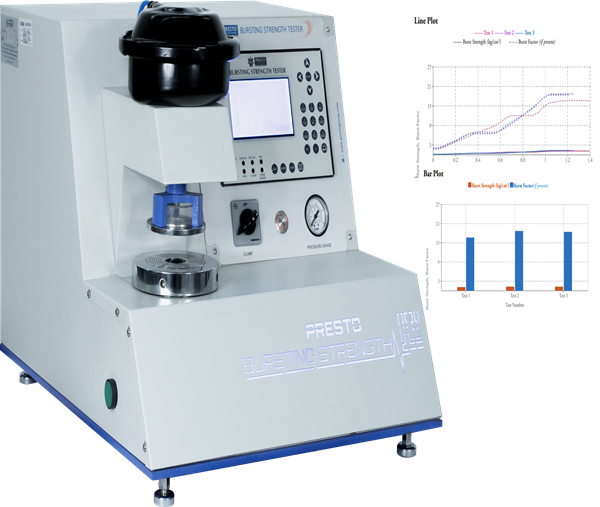

The Digital Pneumatic Bursting Strength Tester is equipped with a digital display and pneumatic clamping system, enabling the determination of bursting strength for various materials such as paper, paperboard, solid fiberboard, and corrugated board and boxes. This equipment is highly valued for its ability to deliver fast and accurate test results, consolidating multiple functionalities into a single instrument.

Read More

The box compression tester digital mini is a paradigm of technology advancement by the Presto Group. The instrument is created to help the manufacturers of small corrugated boxes used for packaging purposes in the bakery industry, minimal accessory industry, etc.

Read More

The Dart Impact Tester Robo 2.0 is more than just a testing device—it is a comprehensive solution for evaluating the strength, durability, and quality of materials under impact conditions. Equipped with a robust frame, intelligent software, and precision mechanics, the Robo 2.0 ensures repeatable results that comply with international testing standards.

Read More

This drop tester operates through a powerful motorised column system that smoothly elevates the test sample to the desired drop height. Once the height is set, its pneumatic clamping and release mechanism securely holds the sample and then releases it instantaneously, ensuring a clean and unbiased free fall.

Read More

Flexible packaging materials like plastic sheets & laminations are used as layering on packaged products & items. These packaged products & items are stacked during transit & storage measures which can cause slipping in the case of less friction between the layers. To avoid such a situation a manufacturer has to ascertain a minimal friction value in the flexible packaging material.

Read More

In Burst Genie 4.0 Digital Bursting Strength Tester Engineered with advanced digital technology, it features a 5-inch LCD display, single-button automatic operation, and intelligent functions like auto peak detection, auto reversal, and pass/fail criteria. This eliminates manual errors, enhances productivity, and ensures repeatable results. What makes the Burst Genie 4.0 unique is its compliance with international testing standards, including ASTM D3786-01, ASTM D3786-80a, IS 1060 Part-1 1987, ASTM D774, ISO 2758, and ISO 2759. Such adherence makes it a globally accepted solution for manufacturers who demand accuracy and reliability in quality control.

Read More

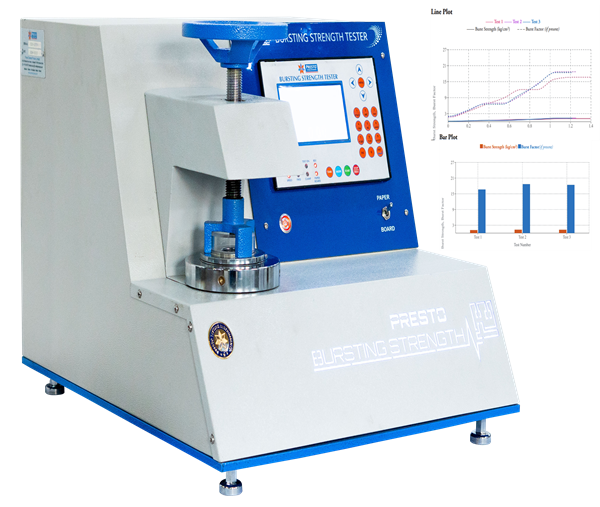

The Bursting Strength Tester Digital cum Computerised Model is a high-precision testing instrument designed to measure the bursting strength of paper, paperboard, corrugated boxes, fabrics, and packaging materials. Equipped with a digital display and advanced computerised software, it delivers accurate results, automated data recording, and reliable performance for quality control and production environments.

Read More

The Bursting Strength Tester Pneumatic Computerized is a high-precision instrument designed to measure the bursting strength of paper, cardboard, fabrics, and packaging materials with exceptional accuracy. Using advanced pneumatic pressure control and a microprocessor-based system, it delivers consistent, repeatable results with minimal operator effort.

Read More

The Bursting Strength Tester – Genie 3.0 is a high-precision, digital testing instrument designed to measure the bursting strength of paper, paperboard, textiles, leather, and packaging materials. Engineered for accuracy, durability, and ease of use, it delivers reliable results for quality control, production testing, and material evaluation across multiple industries.

Read More

Box Compression Tester is a consistent tool to indicate the Compression strength of cardboard boxes so that it does not get deformed or crushed when stacked one above the other during storage or transit.

Read More

Tensile Tester Servo is a reliable, versatile lab instrument for measuring the tensile strength, elongation, and mechanical properties of materials. Suitable for industries like rubber, plastics, automotive, polymers, textiles, and R&D, it delivers accurate results with an easy-to-use interface.

Read More

We are a leading manufacturer and supplier of Tensile Testing Machines with COF (LCD Display), designed for precise measurement of tensile strength, elongation, and coefficient of friction. Our advanced system delivers accurate, real-time results through an easy-to-read LCD display, ensuring dependable performance for material testing in packaging, textiles, plastics, and research industries.

Read More

Laboratory Heat Sealer – Prima Model is a precision tool designed for testing and sealing flexible packaging materials under controlled temperature, pressure, and time settings. It helps manufacturers and laboratories determine the best sealing conditions to ensure package integrity and quality.

Read More

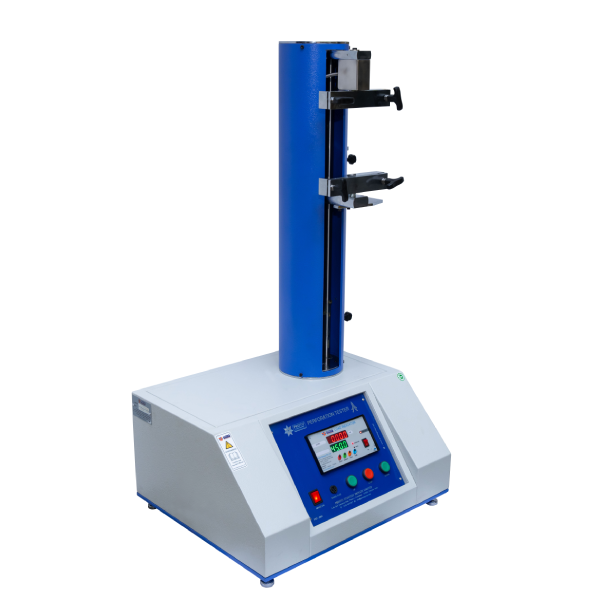

The Perforation Tester is a reliable tool designed to measure the perforation strength or tensile ability of materials such as pouches, thermoplastic films, paper, and packaging. It assesses the efficiency of pre-cut perforations, ensuring proper cohesion of the product while enabling easy separation of consecutive sheets.

Read More

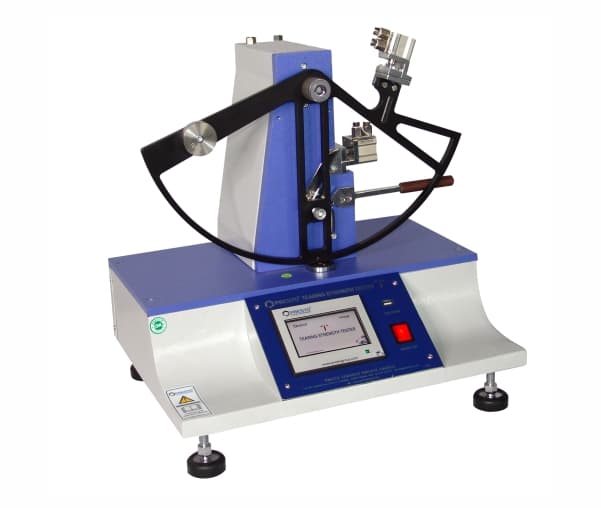

The Tearing Strength Tester – Model No. PTT-560 Prima is a high-precision instrument designed to measure the tearing resistance of flexible materials such as paper, textiles, plastic films, and nonwovens. Based on the Elmendorf pendulum principle, it accurately determines the energy required to propagate a tear in a pre-cut specimen.

Read More

The Presto Dart Impact Tester measures the strength and durability of plastic films by dropping a hemispherical dart from a controlled height. It provides reliable, standard-compliant results to help manufacturers ensure their films can withstand impact and handling.

Read More

The Dart Impact Tester – Prima Series is a high-precision instrument designed to measure the impact resistance of plastic films, laminates, and flexible packaging materials. Using a controlled free-fall dart method, it delivers accurate and repeatable results to help manufacturers evaluate material strength, identify weaknesses, and ensure packaging durability.

Read More

A vibration table is a robust, precision-driven platform designed to deliver controlled vibrations for material compaction, product testing, and quality assurance. Ideal for industrial and laboratory use, it enhances consistency, reduces air gaps, and improves overall production efficiency.

Read More

The Box Compression Tester with optical encoder is a high-precision instrument used to measure the compressive strength and load-bearing capacity of corrugated boxes and packaging materials. Equipped with an advanced optical encoder, it delivers highly accurate displacement and force readings, ensuring reliable quality control in packaging, manufacturing, and logistics industries.

Read More

A Digital Box Compression Tester is a precision instrument used to measure the load-bearing strength of corrugated boxes and packaging materials. It applies controlled compression force to determine how much pressure a box can withstand before collapsing. With accurate digital readings, easy operation, and reliable performance, this tester helps ensure packaging quality.

Read More

The Paper Board Cutter is a precision tool designed for smooth, accurate cutting of paperboards, cardboards, and craft materials. Built with a sharp blade and stable platform, it delivers clean, straight edges with minimal effort. Perfect for printing shops, packaging units, offices, and craft studios, this cutter enhances productivity and ensures professional-quality results in every cut.

Read More

Edge Crush Prima is a premium corrugated packaging grade designed for superior edge strength and dependable load support. Engineered with high-density fibers and advanced construction, it ensures cartons stay firm, stable, and crush-resistant during stacking and transport.

Read More

At Presto, we take pride in being Global manufacturers of Laboratory Testing Instruments for different industries.