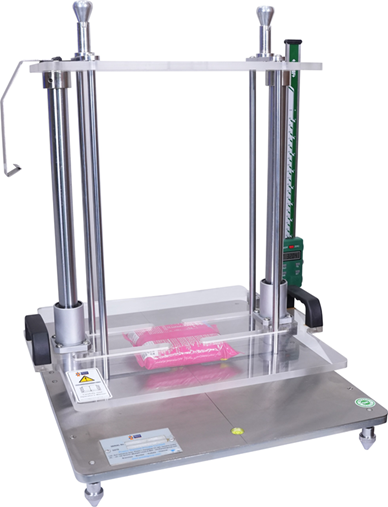

Model : PLHS-24 (500 Mm)

A heat seal tester is a specialized instrument used to evaluate the strength and integrity of a heat seal on packaging materials. Heat seal testers help manufacturers in the food, pharmaceutical, and cosmetics industries determine the strength. The Heat Seal Tester is a laboratory test instrument that determines the sealing strength, temperature, and quality of flexible packaging materials, gauging the compatibility between two layers of material joined under controlled heat, pressure, and dwell time for consistent and reliable seals in packages. time to create a seal and measure the force to pull apart, and evaluate the quality and durability of the seal once created.

A Heat Seal Tester is used to determine the strength and quality of sealing in various packaging materials such as films, foils, and laminates. Using heat and pressure, two layers of material are joined together at specific temperature, pressure, and time settings to check how well they seal and how consistent the sealing is.

A Heat Seal Tester is used to determine the strength and quality of sealing in various packaging materials such as films, foils, and laminates. On the principle of heat and pressure application, two layers of material are sealed together under controlled temperature, pressure, and time conditions to establish their sealing performance and consistency.

Here are the benefits of the heat seal tester explained in detail:

Ensures Seal Integrity

A Heat Seal Tester helps verify the strength and uniformity of seals, ensuring packaging materials prevent leaks or contamination. Testing under controlled conditions allows manufacturers to confirm that their seals remain intact during handling, storage, and transportation and that product safety and extended shelf life are guaranteed.

Enhances Packaging Quality

The Heat Seal Tester gives better assurance of overall packaging quality by determining the optimum combination of temperature, pressure, and sealing time. It enables the manufacturer to produce consistent sealing, minimize material wastage, retain aesthetic appeal, and improve the reliability and performance of the finished packaged product.

Supports product compliance

The tester helps packaging comply with international quality and safety standards such as ASTM and ISO. Regular testing verifies that products are within the purview of regulatory requirements for avoiding recalls or rejections. This instills greater confidence in customers and reinforces a brand's position in highly competitive global markets.

Optimizes Production Efficiency

The Heat Seal Tester allows manufacturers to identify optimal sealing parameters in advance. By minimizing trial-and-error, seal failures, and downtime, it allows the potential for Companies can increase production speeds, reduce costs, and achieve better performance in third-party quality defect rates and material waste.

Here are the applications of the heat seal tester explained in detail:

Food and Beverage Packaging

Heat seal testers possess extensive applications in measuring the strength of seals in pouches, sachets, and containers of food and drinks. Such equipment ensures tight seals that are tamper-proof and prevent spoilage and contamination, ensuring freshness throughout the shelf life and distribution cycle of the product.

Pharmaceutical Packaging

Heat Seal Testers play a critical role in understanding the reliability of seals within blister packs, sachets, and sterile pouches. This is vital to the ongoing efficacy and safety of the medicines after they have been manufactured, packaged, or stored, assuring they are protected from moisture and air, as well as other harmful substances, while being handled or transported.

Consumer Goods and Cosmetics

Manufacturers of consumer and cosmetic products apply Heat Seal Testers to ensure the strength and leak resistance of their packaging. Such tests confirm that tubes, pouches, and wraps remain sealed in different conditions for the protection of the product's texture, fragrance, and overall appeal during transit and use.

Industrial and Chemical Packaging

Heat Seal Testers can also perform testing using heavy-duty packaging materials for the testing of chemicals, adhesives, and lubricants. This is to ensure the seals are strong and reliable by preventing leakage, spillage, and contamination, allowing industrial and hazardous materials to be shipped safely.

Presto Instruments' Heat Seal Tester ensures precision, reliability, and advanced performance in packaging seal testing. Being one of the leading Heat Seal Tester manufacturers, Presto has highly accurate instruments that are designed with cutting-edge technology to test the strength of seals under controlled temperature, pressure, and time conditions.

Presto's equipment exhibits durability, user-friendliness, and compliance with international testing standards like ASTM and ISO. The Presto Heat Seal Tester assists industries in enhancing packaging performance, reducing material wastage, and ensuring consistent seal quality. The company offers excellent after-sales support and calibration services; hence, it is considered one of the perfect partners to rely on for quality assurance in packaging testing.

Presto Instruments is a leading manufacturer and supplier of Laboratory Heat Sealer PLHS-24 (500 Mm). For the best price, contact us for a quote or call now!

| Equipment Range | Ambient to 350ºC |

| Sealing T emperature Working range | Ambient to 230ºC |

| Accuracy | ± 1ºC |

| Least Count/Resolution | 0.1ºC |

| Power | 220V , Single phase, 50 Hz |

| Sealing size** | 500x15mm and 150x 15 mm OR 300x 15 mm |

| Temperature Controller | 4 digit PID |

| Dwell Heat Seal time | 0.5 – 99.9 sec |

| Timer | 4 Digit Digital |

| Heat Sensor | Pt-100, Platinum Resistance Temperature Detector (RTD) |

| Sealing Pressure | 2 - 6 Bar |

| Anti-vibration Pad | Specially designed to reduce the effect of the vibration |

Highlights:

| Temperature Controller | PID 7 segment display |

| Timer | Digital Preset type |

| Heat Source | Cartridge Heaters |

| Seal Pattern | Straight line, Plain & Diamond Knurling (select any one pattern) |

| T est Performed | Heat Steel |

The Heat Seal Tester is a laboratory test instrument designed to determine the sealing strength, temperature, and quality of flexible packaging materials. It gauges the compatibility between two layers of material joined under controlled heat, pressure, and dwell time for consistent and reliable seals in packages.

A Heat Seal Tester can be used for flexible packaging materials like plastic films, laminated foils, coated papers, composite sheets, and other materials commonly used for packaging food, pharmaceuticals, and consumer goods, ensuring that the seals are leak-proof and strong.

Heat seal testing is crucial in maintaining product safety and freshness for its shelf life. It helps in determining the ideal sealing parameters for a package to avoid leaks, contamination, or weak seals during production and storage. This process ensures consistent packaging quality and compliance with international testing standards.

Various heat seal testers come at varying prices, fluctuating approximately between ₹15,000 and ₹200,000 or more, depending on the features and model. Basic, simple digital models may be available within a range of ₹40,000 to ₹55,000, but an advanced lab-grade or automated unit would cost much more.

The testing of heat seals is generally done by following international norms like ASTM F2029, ASTM F88, and ISO 11607. These standards have defined test methods that must be performed to ensure the quality and safety of the packaging materials for sealing strength and performance.

The Presto Melt Flow Index Tester is your go-to solution to evaluate the flow properties of molten plastics or resins. This tester is designed to measure the Melt Flow Index of thermoplastic materials and, hence, determines the rate of flow in grams per ten minutes of molten resins through a specific jet length and diameter.

Read More

The Melt Flow Index Tester – NEO 2.0 is a high-precision instrument designed to measure the melt flow rate (MFR) of thermoplastic polymers under controlled temperature and load. Built with advanced digital controls, automated cutting, and durable construction, the NEO 2.0 ensures accurate, repeatable, and efficient testing for laboratories, research centers, and plastic manufacturing industries. It fully complies with ASTM D1238 and ISO 1133 standards.

Read More

Melt Flow Index – NEO 2.0 is a high-precision polymer testing instrument designed to measure the melt flow rate (MFR) and melt volume rate (MVR) of thermoplastics. Equipped with advanced digital controls, automatic operation, and compliance with international standards, it delivers accurate, repeatable, and reliable results for quality control, R&D, and industrial applications.

Read More

The Notch Cutter Motorised Impact Tester NC 22 is a precision laboratory instrument designed for accurate and repeatable notch preparation of Charpy and Izod test specimens. Featuring motorized operation, adjustable cutting depth, and robust construction, it ensures consistent, standard-compliant notches with minimal operator effort. Ideal for quality control, research, and material testing labs, the NC 22 combines precision, safety, and ease of use in a compact, durable design.

Read More

A Tube Burst Tester is a precision instrument used to measure the internal pressure strength of tubes, hoses, and flexible packaging. It determines the exact burst point to ensure product durability, safety, and compliance with industry standards. Ideal for pharmaceuticals, cosmetics, food packaging, and industrial tubing, this tester provides accurate, reliable data for quality control and R&D applications.

Read More

The Presto Fill Height Gauge is a valuable laboratory instrument designed to enhance efficiency and precision in measuring container fill heights and volumes.

Read More

The UL-94 Flammability Tester is a high-precision instrument for testing the flammability of plastic materials. It provides reliable vertical and horizontal flame testing in accordance with the UL 94 standard, making it ideal for quality control and material compliance across multiple industries.

Read More

A Flip Cap Opening Tester measures the force needed to open flip-top caps, ensuring consistent quality, ease of use, and durability in packaging. It provides accurate, repeatable results to help manufacturers verify cap performance and maintain product standards.

Read More

Presto's Hot Tack Tester is a highly efficient testing instrument designed for conducting hot tack tests and evaluating heat seal performance in laminated films, plastic films, and various packaging products.

Read More

The Presto Illuminated Inspection Magnifier is a reliable tool for manufacturers to test small components and parts using a magnifying glass. It features a convex lens to achieve a magnified image of the object under inspection.

Read More

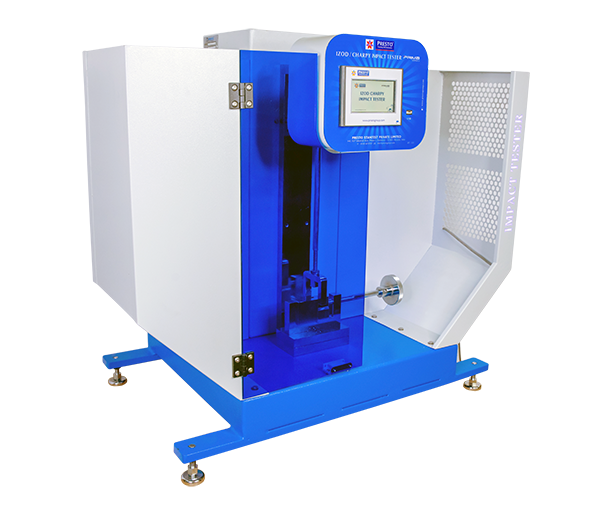

The Izod/Charpy Impact Tester Digital is a dual-purpose instrument designed to accurately measure the impact strength of materials using both Izod and Charpy methods. Featuring a high-precision digital display and a durable pendulum system, it delivers reliable, repeatable results for quality control and laboratory testing.

Read More

The Heat Sealer Prima is a reliable tool designed for sealing flexible packaging products and thermoplastic materials by applying pressure and heat at high temperatures.

Read More

A precision motorised notch cutter designed for Charpy and Izod impact test specimens. Ensures consistent and accurate notches, enhancing test reliability and repeatability. Features adjustable cutting depth, robust construction, and safety mechanisms, making it ideal for laboratories, quality control, and materials research.

Read More

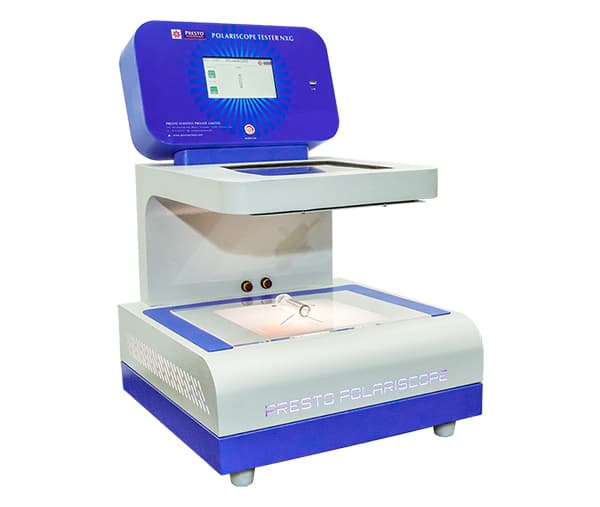

Polariscope Strain Viewer Computerised is a modern optical inspection system designed to detect and analyze internal stresses in transparent materials with high precision. Using polarized light, digital imaging, and advanced software, it provides clear visualization of strain patterns, real-time analysis, and accurate reporting.

Read More

The Polariscope-Dx for PET & Preform is a high-precision optical inspection system designed to reveal internal stresses, birefringence, and flow irregularities in PET preforms and bottles. Using polarized light and advanced illumination, it helps manufacturers optimize molding conditions, improve product strength and clarity, and reduce production defects. Ideal for PET processing plants, QA labs, and R&D departments, the Polariscope-Dx ensures c

Read More

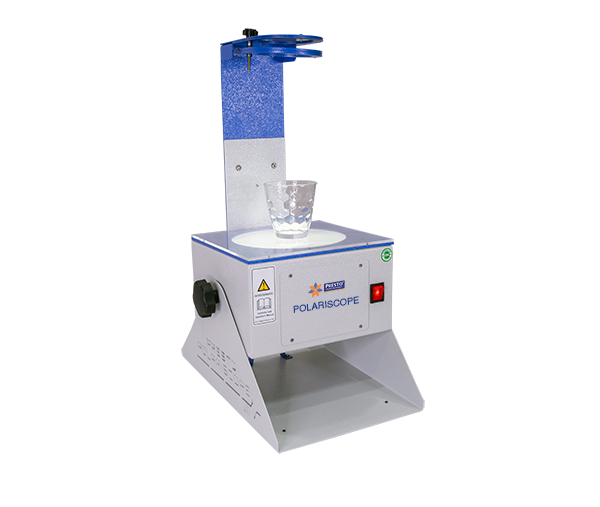

Presto's Glass & Plastic Polariscope - Strain Viewer stands out as the premier and highly efficient testing device for measuring residual stresses and strains introduced during the manufacturing process of transparent glass

Read More

The Polariscope Strain Viewer – NXG is a next-generation optical inspection device designed to reveal internal stress and birefringence in transparent materials with exceptional clarity. Featuring advanced polarized-light technology, uniform LED illumination, and an easy-to-use viewing platform, the NXG delivers fast, accurate, and non-destructive strain analysis for glass, plastics, optical parts, and molded components.

Read More

The Preform Eccentricity Tester is a trusted instrument that manufacturers use for the measurement of the eccentricity of PET preforms.

Read More

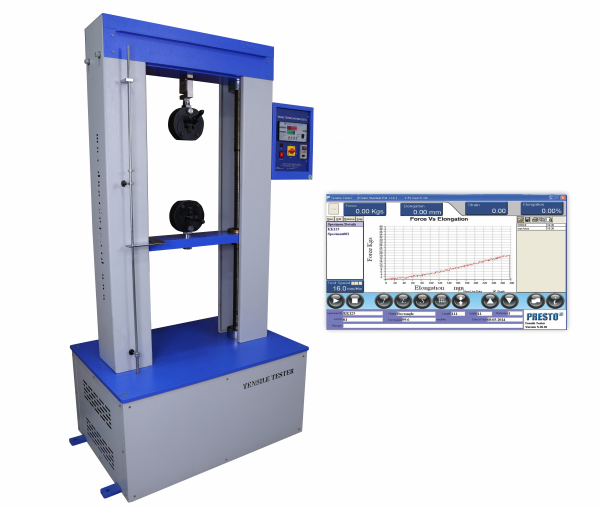

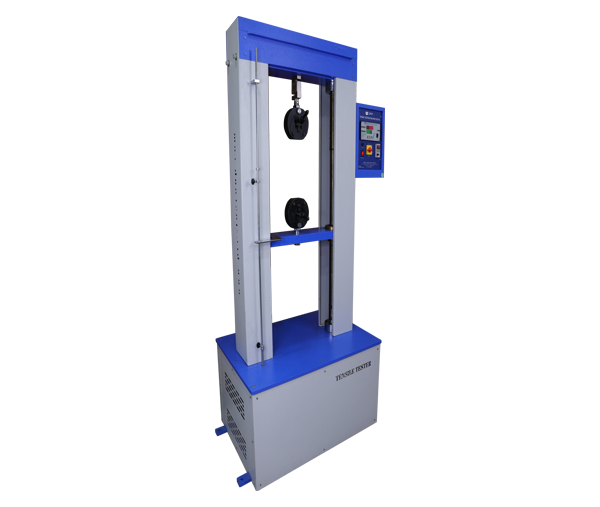

Tensile strength is the stress level at which a material breaks or undergoes permanent deformation. The PRESTO Digital Tensile Tester is a cutting-edge,

Read More

The Tensile Testing Machine (Cap.: 10000 kgf) Digital is a precision-engineered testing system designed to measure the tensile strength, elongation, and mechanical properties of various materials such as metals, plastics, rubber, and composites. Equipped with a high-accuracy digital load indicator and elongation measurement system, it provides reliable, real-time test data for quality control and research applications.

Read More

The Air Bulge Tester is a precision device used to measure the pressure strength and deformation of films, paper, and sheet materials. By applying controlled air pressure, it accurately evaluates how materials stretch, bulge, and fail, making it essential for quality control, research, and industrial testing applications.

Read More

The Flammability Tester for Wires and Cables is a precision testing instrument designed to evaluate the flame-retardant properties of electrical wires and cables. It measures burning behavior, flame spread, and self-extinguishing performance to ensure compliance with international safety standards like IEC, UL, ASTM, and ISO. Ideal for manufacturers, R&D labs, and quality control, it enhances product safety, reliability, and fire resistance.

Read More

The Melt Flow Index – MFR Model offers significant benefits, including accurate testing, stable thermal control, and durable construction for long-term use. It supports industries such as injection molding, extrusion, film production, and plastic recycling, where melt flow properties directly impact product quality and production efficiency.

Read More

A Tensile Testing Machine Digital is a precision testing instrument designed to measure the tensile strength, elongation, and other mechanical properties of various materials such as metals, polymers, rubber, textiles, and components.

Read More

A Heat Deformation Tester is a precision instrument designed to measure the Heat Deflection Temperature (HDT) and Vicat Softening Point (VSP) of plastics and polymer materials. It provides accurate thermal performance data, helping manufacturers ensure product quality, durability, and compliance with global testing standards.

Read More

The IZOD/Charpy Impact Tester NXG Model is a high-precision, dual-mode impact testing machine engineered for accurate measurement of material toughness. With advanced sensors, robust construction, and support for international standards, it delivers fast, reliable, and repeatable results for metals, plastics, and composite materials across QC labs, manufacturing, and research environments.

Read More

The Izod / Charpy Impact Tester Computerized is a precision instrument designed to measure the impact strength and toughness of materials such as plastics, metals, and composites. Equipped with advanced sensors and automated software, it delivers accurate, repeatable Izod and Charpy test results with real-time digital analysis—ideal for laboratories, research facilities, and quality control applications.

Read More

The Carbon Black Dispersion Test Apparatus is a high-precision instrument used to assess the uniform dispersion of carbon black in rubber and polymer materials. Using advanced microscopy and standardized grading methods, it identifies particle distribution, agglomeration, and mixing quality to ensure superior material strength and consistency. Ideal for QA/QC labs, tire manufacturers, and rubber processing industries.

Read More

The Carbon Black Content Apparatus accurately measures the carbon black content in various materials, making it an essential tool for laboratories, R&D centers, and industrial production facilities. Its user-friendly design, fast testing capabilities, and adherence to industry standards make it the ideal choice for quality control and material analysis.

Read More

The Digital Specific Gravity Balance is a precision instrument used to measure the density or specific gravity of rubber, plastic, and other materials. It works on Archimedes’ principle and provides quick, accurate digital results. Ideal for quality control and lab testing, it features simple operation and a clear digital display.

Read More

The Presto Muffle Furnace HMI - PRIMA Series is a reliable laboratory furnace used to measure ash content and analyze material properties. With a user-friendly touch screen interface, it allows precise temperature control and automatic heating. Suitable for industries like metal, agriculture, medical research, rubber, and wool.

Read More

The Flammability Tester IS 15061 is a high-precision instrument designed to evaluate the burning resistance and flame spread properties of textiles and fabrics as per IS 15061 standards. Engineered with a stainless-steel test chamber, controlled flame system, and digital timer, it delivers accurate, repeatable results for quality control, research, and compliance testing.

Read More

At Presto, we take pride in being Global manufacturers of Laboratory Testing Instruments for different industries.