Model : TTM-D (as per capacity)

An impact tester is an advanced testing tool used to test the toughness and resistance to impact of materials by measuring the absorbed energy at fracture under sudden or dynamic loading conditions. It measures well the ability of a material to resist shock or impact loads, which is important in determining performance and longevity in severe industrial environments. Standard configurations are pendulum and drop-weight systems, while Charpy and Izod impact testers are used most commonly. The instruments provide consistent quality control and material certification across industries like automotive, aerospace, construction, and manufacturing.

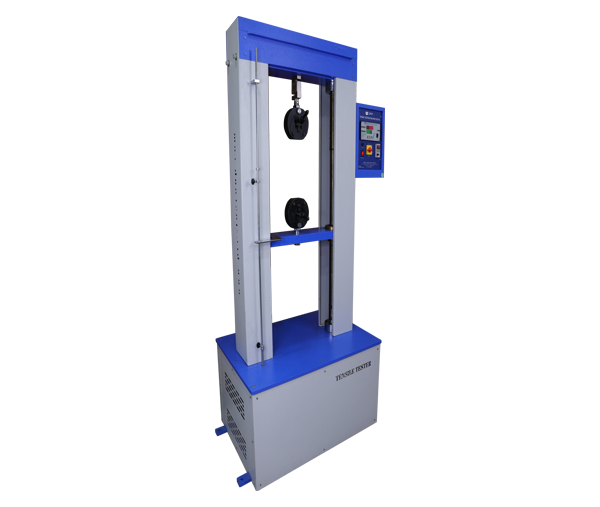

A tensile strength testing machine is a specialized apparatus designed to evaluate a material’s behavior when subjected to tension. It measures key material properties such as tensile strength, elongation, yield point, and modulus of elasticity. During a test, the specimen is securely gripped and subjected to a controlled tensile load until failure occurs. The resulting deformation data reveals essential insights into the material’s quality, strength, and performance characteristics, ensuring reliability and compliance with required specifications.

The tensile testing machine applies a steadily increasing tensile load to a specimen that is clamped between two precision grips. As the load increases, the machine continuously records the applied force and the corresponding elongation of the specimen using highly accurate sensors.

The collected data is used to generate a stress-strain curve, which provides detailed mechanical properties such as:

By analyzing these parameters, manufacturers and engineers can assess the quality, performance, and conformity of materials, ensuring safe and efficient product design.

1. Accurate Material Characterization

The machine delivers precise measurements of mechanical properties like tensile strength, elongation, and elasticity. This helps manufacturers understand how materials behave under load, ensuring safe and reliable design and production.

2. Quality Assurance

Before materials enter production, tensile testing confirms they meet defined quality standards. This process detects potential defects, improving consistency, reliability, and reducing failure risks across manufacturing operations.

3. Product Development Support

During R&D, tensile testing helps evaluate new materials and improve existing formulations. Insights from these tests allow engineers to refine designs, optimize performance, and meet strict durability requirements.

4. Compliance with International Standards

Presto tensile strength testers comply with ASTM, ISO, and other global standards, ensuring your products meet certification and customer requirements for performance and safety.

5. Failure Analysis and Troubleshooting

By examining how and when a material fails, tensile testing assists in identifying weak points and improving material formulations. This minimizes product recalls, warranty claims, and production costs.

Metal and Alloy Testing

Used to determine the tensile strength, ductility, and elasticity of metals and alloys. Ensures the safety and performance of materials used in construction, automotive, and aerospace applications.

Plastic and Polymer Testing

Evaluates tensile properties of plastic sheets, films, and molded parts, helping manufacturers ensure flexibility, durability, and performance in both processing and end-use conditions.

Textile and Fabric Testing

Determines the tensile strength and elongation of yarns, fabrics, and fibers, ensuring products meet required standards for durability and comfort.

Rubber and Elastomer Testing

Assesses the stretch, strength, and resilience of rubber materials—crucial for components like tires, seals, and gaskets that require elasticity under load.

Composite Material Testing

Measures the load-bearing capacity and bonding integrity of composites used in aerospace, sports, and automotive industries, ensuring lightweight materials meet structural performance demands.

Research and Development

Tensile testers are essential in R&D for developing innovative materials, improving formulations, and validating performance parameters before commercialization.

The Presto Tensile Strength Testing Machine is a robust, high-precision instrument engineered for consistent and repeatable testing results. Featuring advanced load cells, digital control systems, and durable construction, it provides accurate analysis of tensile strength, elongation, and other mechanical properties.

Designed to comply with ASTM and ISO standards, it ensures international reliability and confidence. Its user-friendly interface, ergonomic design, and long-lasting performance make it suitable for both laboratory and production environments.

With Presto Instruments, you get more than a machine — you get dependable service support, calibration, and technical expertise, making Presto a trusted name in material testing and quality assurance.

Presto Instruments is a leading manufacturer and supplier of Digital Tensile Testing Machine Cap 2500KG For the best price, contact us for a quote or call now!

This machine is designed to perform tensile tests on materials and products — that is, to apply a pulling force until deformation or breakage occurs, so that you can measure properties such as maximum tensile load, elongation, and strength.

It means the maximum load (capacity) that the machine is rated to handle is about 2,500 kg (or 2.5 tonnes) in tensile testing mode. This ensures that samples up to that maximum force can be tested safely.

It uses the Constant Rate of Traverse (CRT) principle — a fixed speed of movement of the cross-head which applies the tensile force to the specimen between two grips.

The machine includes features like:

Over-load protection

Over-travel limit switches

Hardened lead screws for frictionless movement and stability

This depends on the manufacturer/supplier. For the referenced model by PRESTO, they offer technical support, training service, relocation assistance, maintenance support and parts supply.

The Presto Melt Flow Index Tester is your go-to solution to evaluate the flow properties of molten plastics or resins. This tester is designed to measure the Melt Flow Index of thermoplastic materials and, hence, determines the rate of flow in grams per ten minutes of molten resins through a specific jet length and diameter.

Read More

The Melt Flow Index Tester – NEO 2.0 is a high-precision instrument designed to measure the melt flow rate (MFR) of thermoplastic polymers under controlled temperature and load. Built with advanced digital controls, automated cutting, and durable construction, the NEO 2.0 ensures accurate, repeatable, and efficient testing for laboratories, research centers, and plastic manufacturing industries. It fully complies with ASTM D1238 and ISO 1133 standards.

Read More

Melt Flow Index – NEO 2.0 is a high-precision polymer testing instrument designed to measure the melt flow rate (MFR) and melt volume rate (MVR) of thermoplastics. Equipped with advanced digital controls, automatic operation, and compliance with international standards, it delivers accurate, repeatable, and reliable results for quality control, R&D, and industrial applications.

Read More

The Notch Cutter Motorised Impact Tester NC 22 is a precision laboratory instrument designed for accurate and repeatable notch preparation of Charpy and Izod test specimens. Featuring motorized operation, adjustable cutting depth, and robust construction, it ensures consistent, standard-compliant notches with minimal operator effort. Ideal for quality control, research, and material testing labs, the NC 22 combines precision, safety, and ease of use in a compact, durable design.

Read More

A Tube Burst Tester is a precision instrument used to measure the internal pressure strength of tubes, hoses, and flexible packaging. It determines the exact burst point to ensure product durability, safety, and compliance with industry standards. Ideal for pharmaceuticals, cosmetics, food packaging, and industrial tubing, this tester provides accurate, reliable data for quality control and R&D applications.

Read More

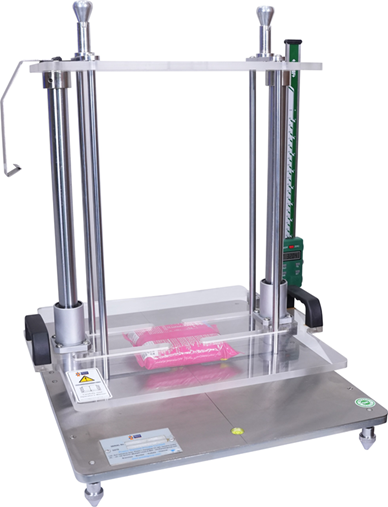

The Presto Fill Height Gauge is a valuable laboratory instrument designed to enhance efficiency and precision in measuring container fill heights and volumes.

Read More

The UL-94 Flammability Tester is a high-precision instrument for testing the flammability of plastic materials. It provides reliable vertical and horizontal flame testing in accordance with the UL 94 standard, making it ideal for quality control and material compliance across multiple industries.

Read More

A Flip Cap Opening Tester measures the force needed to open flip-top caps, ensuring consistent quality, ease of use, and durability in packaging. It provides accurate, repeatable results to help manufacturers verify cap performance and maintain product standards.

Read More

Presto's Hot Tack Tester is a highly efficient testing instrument designed for conducting hot tack tests and evaluating heat seal performance in laminated films, plastic films, and various packaging products.

Read More

The Presto Illuminated Inspection Magnifier is a reliable tool for manufacturers to test small components and parts using a magnifying glass. It features a convex lens to achieve a magnified image of the object under inspection.

Read More

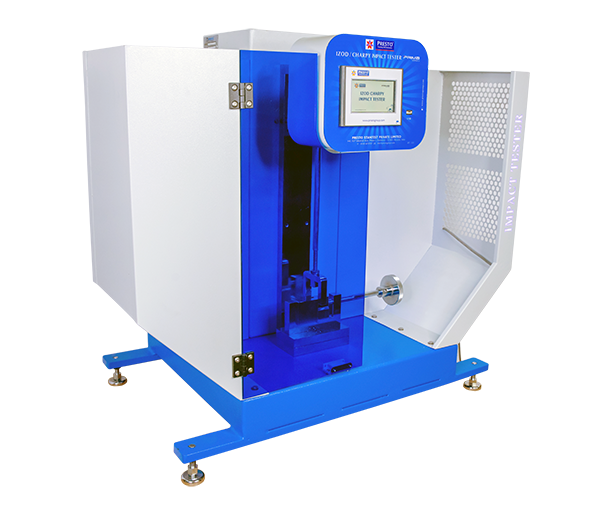

The Izod/Charpy Impact Tester Digital is a dual-purpose instrument designed to accurately measure the impact strength of materials using both Izod and Charpy methods. Featuring a high-precision digital display and a durable pendulum system, it delivers reliable, repeatable results for quality control and laboratory testing.

Read More

The Heat Sealer Prima is a reliable tool designed for sealing flexible packaging products and thermoplastic materials by applying pressure and heat at high temperatures.

Read More

The Presto Pneumatic Model Heat Sealer is a staple in the plastic industry, renowned for its versatility and reliability. Featuring adjustable temperature settings, this heat sealer is equipped with a digital display and operates on a microprocessor-based system.

Read More

A precision motorised notch cutter designed for Charpy and Izod impact test specimens. Ensures consistent and accurate notches, enhancing test reliability and repeatability. Features adjustable cutting depth, robust construction, and safety mechanisms, making it ideal for laboratories, quality control, and materials research.

Read More

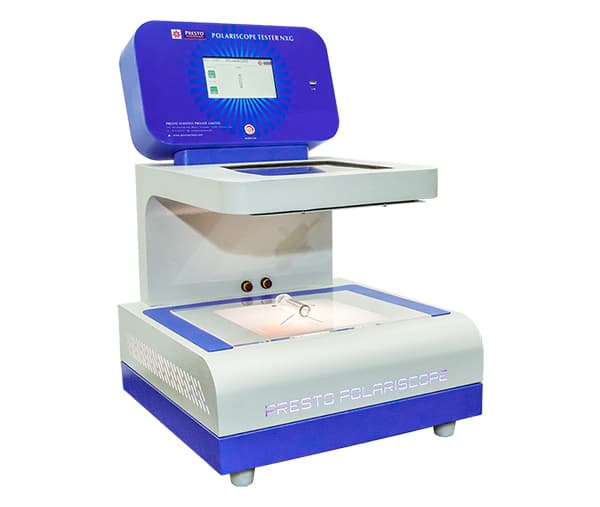

Polariscope Strain Viewer Computerised is a modern optical inspection system designed to detect and analyze internal stresses in transparent materials with high precision. Using polarized light, digital imaging, and advanced software, it provides clear visualization of strain patterns, real-time analysis, and accurate reporting.

Read More

The Polariscope-Dx for PET & Preform is a high-precision optical inspection system designed to reveal internal stresses, birefringence, and flow irregularities in PET preforms and bottles. Using polarized light and advanced illumination, it helps manufacturers optimize molding conditions, improve product strength and clarity, and reduce production defects. Ideal for PET processing plants, QA labs, and R&D departments, the Polariscope-Dx ensures c

Read More

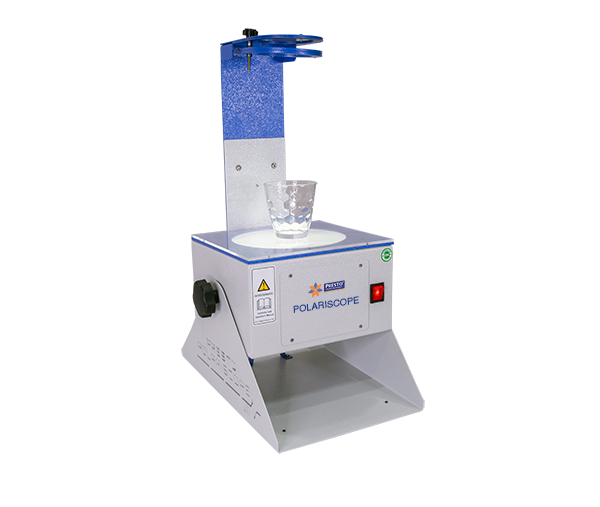

Presto's Glass & Plastic Polariscope - Strain Viewer stands out as the premier and highly efficient testing device for measuring residual stresses and strains introduced during the manufacturing process of transparent glass

Read More

The Polariscope Strain Viewer – NXG is a next-generation optical inspection device designed to reveal internal stress and birefringence in transparent materials with exceptional clarity. Featuring advanced polarized-light technology, uniform LED illumination, and an easy-to-use viewing platform, the NXG delivers fast, accurate, and non-destructive strain analysis for glass, plastics, optical parts, and molded components.

Read More

The Preform Eccentricity Tester is a trusted instrument that manufacturers use for the measurement of the eccentricity of PET preforms.

Read More

The Tensile Testing Machine (Cap.: 10000 kgf) Digital is a precision-engineered testing system designed to measure the tensile strength, elongation, and mechanical properties of various materials such as metals, plastics, rubber, and composites. Equipped with a high-accuracy digital load indicator and elongation measurement system, it provides reliable, real-time test data for quality control and research applications.

Read More

The Air Bulge Tester is a precision device used to measure the pressure strength and deformation of films, paper, and sheet materials. By applying controlled air pressure, it accurately evaluates how materials stretch, bulge, and fail, making it essential for quality control, research, and industrial testing applications.

Read More

The Flammability Tester for Wires and Cables is a precision testing instrument designed to evaluate the flame-retardant properties of electrical wires and cables. It measures burning behavior, flame spread, and self-extinguishing performance to ensure compliance with international safety standards like IEC, UL, ASTM, and ISO. Ideal for manufacturers, R&D labs, and quality control, it enhances product safety, reliability, and fire resistance.

Read More

The Melt Flow Index – MFR Model offers significant benefits, including accurate testing, stable thermal control, and durable construction for long-term use. It supports industries such as injection molding, extrusion, film production, and plastic recycling, where melt flow properties directly impact product quality and production efficiency.

Read More

A Tensile Testing Machine Digital is a precision testing instrument designed to measure the tensile strength, elongation, and other mechanical properties of various materials such as metals, polymers, rubber, textiles, and components.

Read More

A Heat Deformation Tester is a precision instrument designed to measure the Heat Deflection Temperature (HDT) and Vicat Softening Point (VSP) of plastics and polymer materials. It provides accurate thermal performance data, helping manufacturers ensure product quality, durability, and compliance with global testing standards.

Read More

The IZOD/Charpy Impact Tester NXG Model is a high-precision, dual-mode impact testing machine engineered for accurate measurement of material toughness. With advanced sensors, robust construction, and support for international standards, it delivers fast, reliable, and repeatable results for metals, plastics, and composite materials across QC labs, manufacturing, and research environments.

Read More

The Izod / Charpy Impact Tester Computerized is a precision instrument designed to measure the impact strength and toughness of materials such as plastics, metals, and composites. Equipped with advanced sensors and automated software, it delivers accurate, repeatable Izod and Charpy test results with real-time digital analysis—ideal for laboratories, research facilities, and quality control applications.

Read More

The Carbon Black Dispersion Test Apparatus is a high-precision instrument used to assess the uniform dispersion of carbon black in rubber and polymer materials. Using advanced microscopy and standardized grading methods, it identifies particle distribution, agglomeration, and mixing quality to ensure superior material strength and consistency. Ideal for QA/QC labs, tire manufacturers, and rubber processing industries.

Read More

The Carbon Black Content Apparatus accurately measures the carbon black content in various materials, making it an essential tool for laboratories, R&D centers, and industrial production facilities. Its user-friendly design, fast testing capabilities, and adherence to industry standards make it the ideal choice for quality control and material analysis.

Read More

The Digital Specific Gravity Balance is a precision instrument used to measure the density or specific gravity of rubber, plastic, and other materials. It works on Archimedes’ principle and provides quick, accurate digital results. Ideal for quality control and lab testing, it features simple operation and a clear digital display.

Read More

The Presto Muffle Furnace HMI - PRIMA Series is a reliable laboratory furnace used to measure ash content and analyze material properties. With a user-friendly touch screen interface, it allows precise temperature control and automatic heating. Suitable for industries like metal, agriculture, medical research, rubber, and wool.

Read More

The Flammability Tester IS 15061 is a high-precision instrument designed to evaluate the burning resistance and flame spread properties of textiles and fabrics as per IS 15061 standards. Engineered with a stainless-steel test chamber, controlled flame system, and digital timer, it delivers accurate, repeatable results for quality control, research, and compliance testing.

Read More

At Presto, we take pride in being Global manufacturers of Laboratory Testing Instruments for different industries.